Real World Applications of Best Industrial Motors in Different Industries

In today's industrial landscape, the efficiency and reliability of operations heavily depend on the type of equipment used, with industrial motors playing a pivotal role. According to the International Electrotechnical Commission (IEC), the global industrial motor market is projected to reach $57 billion by 2027, driven by the increasing demand for energy efficiency and automation across various sectors. This demand highlights not only the importance of selecting the best industrial motors but also the significance of robust after-sales services and effective maintenance strategies. Studies indicate that maintenance costs can account for 15-40% of a facility's total operating budget, underscoring the need for reliable service agreements and timely repairs.

In today's industrial landscape, the efficiency and reliability of operations heavily depend on the type of equipment used, with industrial motors playing a pivotal role. According to the International Electrotechnical Commission (IEC), the global industrial motor market is projected to reach $57 billion by 2027, driven by the increasing demand for energy efficiency and automation across various sectors. This demand highlights not only the importance of selecting the best industrial motors but also the significance of robust after-sales services and effective maintenance strategies. Studies indicate that maintenance costs can account for 15-40% of a facility's total operating budget, underscoring the need for reliable service agreements and timely repairs.

Thus, understanding the real-world applications of these motors, coupled with actionable tips for optimizing their performance, can lead to substantial cost savings and improved operational efficiency across different industries.

Real World Applications of Industrial Motors: A Comparative Study Across Core Sectors

In today's fast-paced industrial landscape, the application of industrial motors spans various sectors, showcasing their versatility and crucial role in operational efficiency. According to a report by ResearchAndMarkets, the global industrial motor market is projected to reach $154 billion by 2026, driven by the increasing demand for automation and energy-efficient technologies.

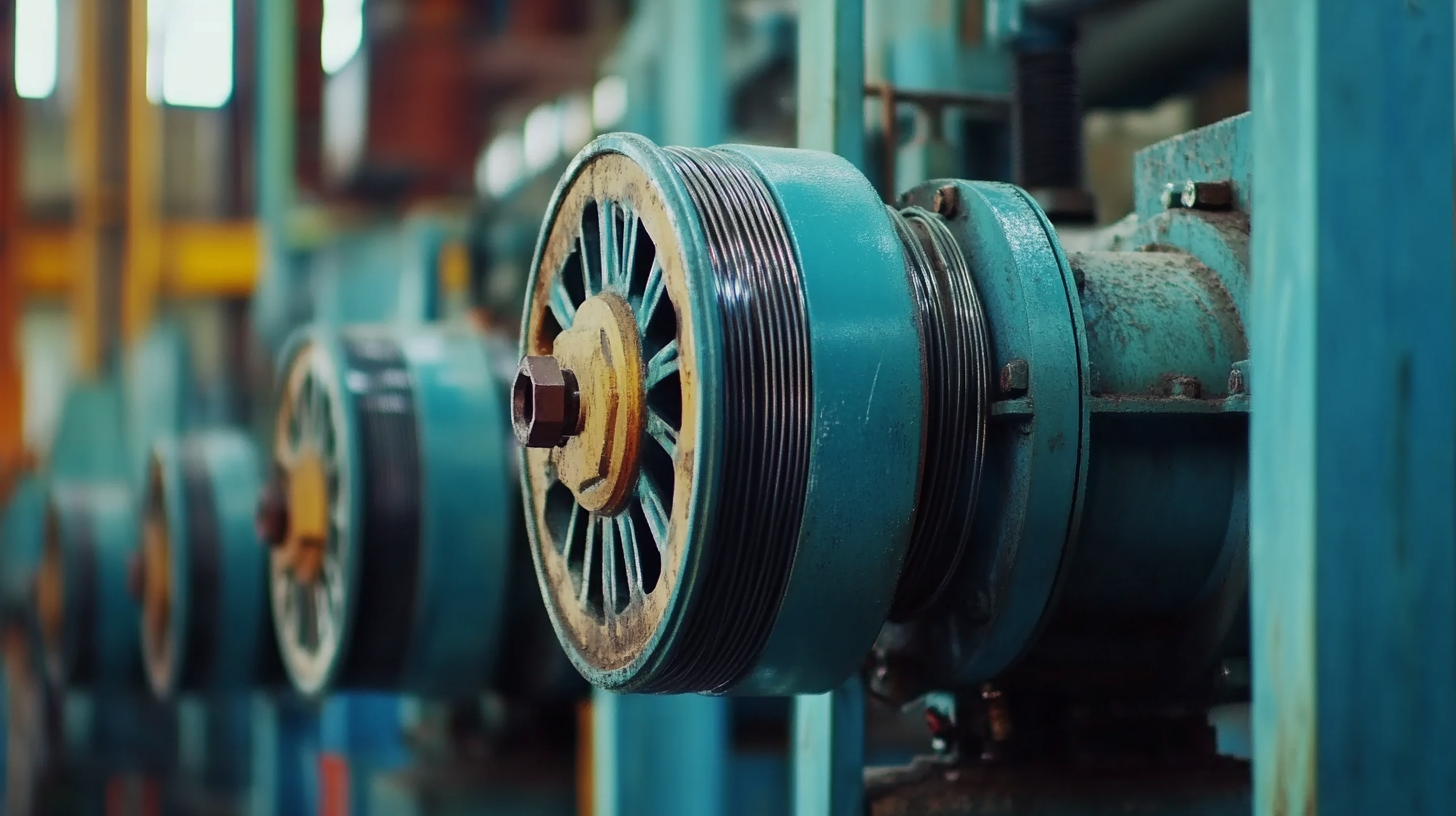

Various industries, from manufacturing and construction to oil and gas, utilize different types of motors tailored to specific applications, significantly enhancing productivity.

In the manufacturing sector, for instance, AC and DC motors are utilized for their precision and reliability in driving conveyor belts and assembly lines. The International Electrotechnical Commission (IEC) reports that energy-efficient motors can reduce energy consumption by up to 50% compared to standard motors. Meanwhile, in the oil and gas industry, explosion-proof motors are essential for operation in hazardous environments, ensuring safety without compromising performance. This comparative analysis highlights how adopting the right industrial motors boosts operational efficiency while adhering to safety and environmental standards across core sectors.

Examining the Role of Electric Motors in Manufacturing: Efficiency and Cost Benefits

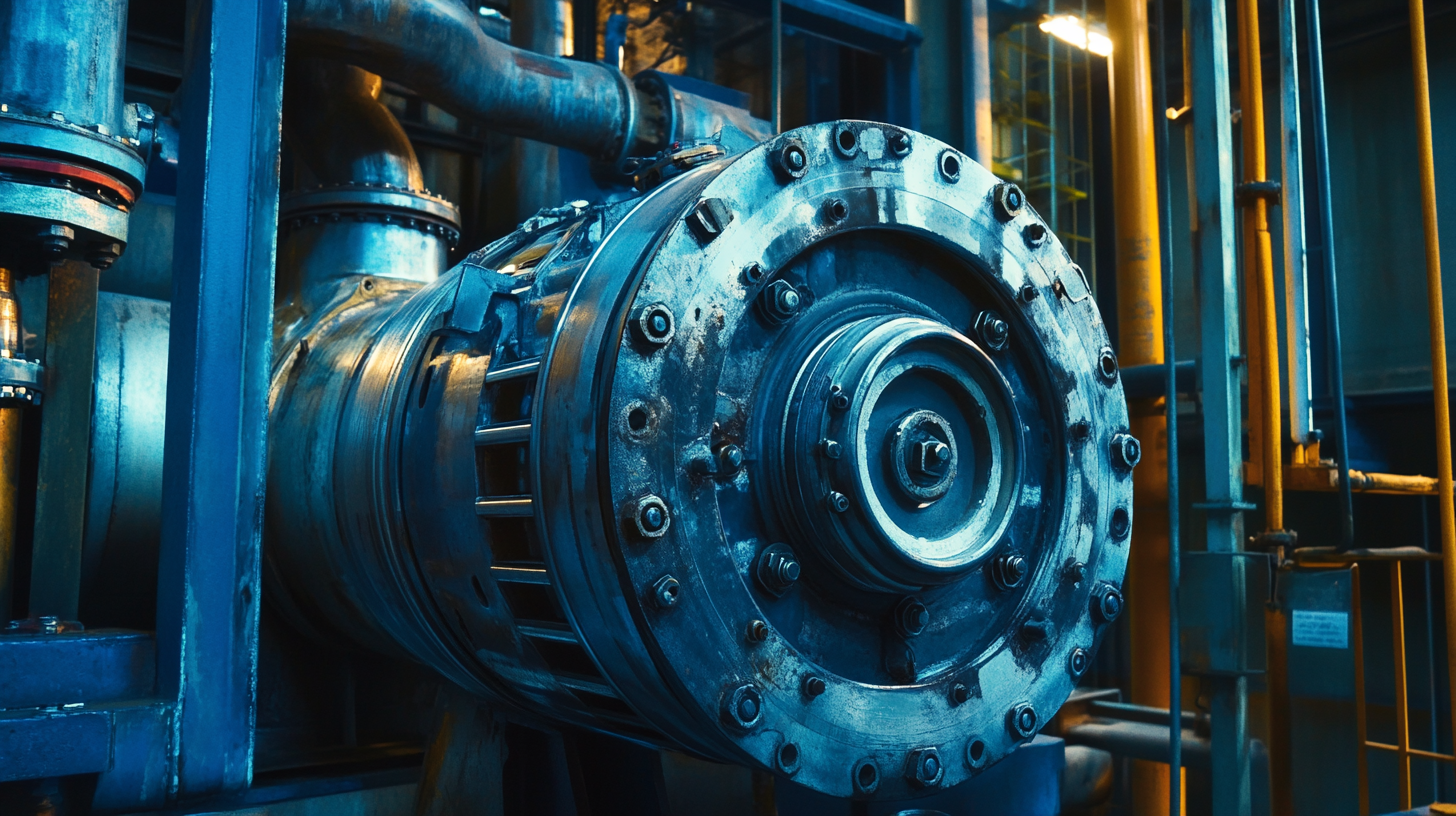

Electric motors play a crucial role in various manufacturing processes, driving efficiency and reducing operational costs. By converting electrical energy into mechanical energy, these motors facilitate movement and automation in machinery, leading to enhanced productivity.

The implementation of high-efficiency industrial motors can contribute significantly to energy savings, which is particularly beneficial for companies looking to minimize their carbon footprint while maximizing output.

Electric motors play a crucial role in various manufacturing processes, driving efficiency and reducing operational costs. By converting electrical energy into mechanical energy, these motors facilitate movement and automation in machinery, leading to enhanced productivity.

The implementation of high-efficiency industrial motors can contribute significantly to energy savings, which is particularly beneficial for companies looking to minimize their carbon footprint while maximizing output.

Tip: When selecting electric motors for your production line, consider the specific applications and the operational environment. Opt for motors that offer high torque and low energy consumption to optimize performance.

In addition to energy efficiency, electric motors provide cost benefits through decreased maintenance requirements and longer lifespan. Modern technologies, such as variable frequency drives (VFDs), further enhance control over motor speed and efficiency, allowing manufacturers to adjust power usage according to demand. This adaptability can lead to substantial cost reductions over time.

Tip: Regular maintenance and monitoring of electric motors can prevent unexpected failures. Investing in predictive maintenance systems can help identify potential issues early, ensuring smooth operations and reducing downtime costs.

Exploring Motion Control: How Motors Drive Innovations in Robotics and Automation

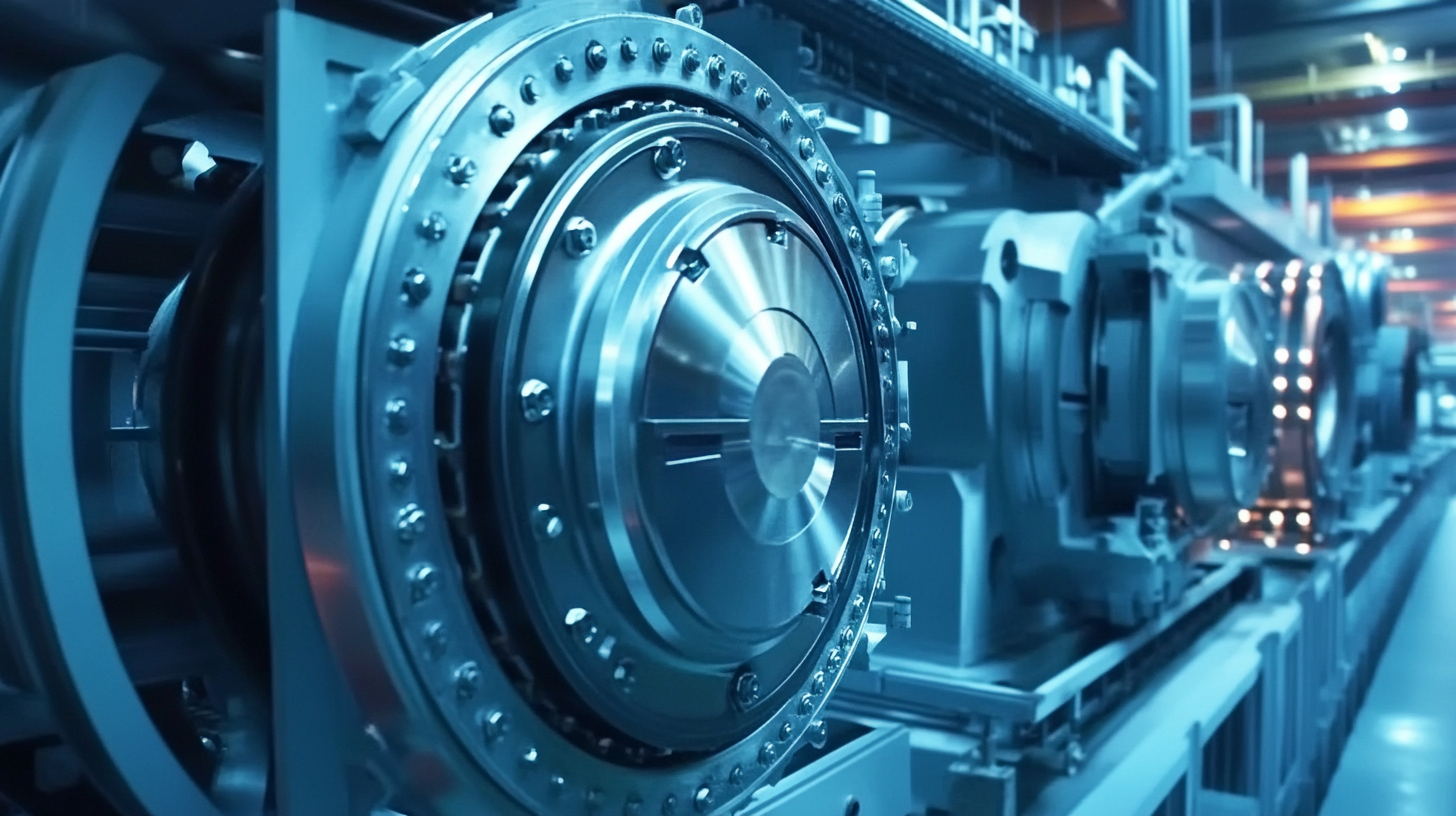

In today's rapidly evolving technological landscape, the role of motors in robotics and automation cannot be overstated. According to a report by MarketsandMarkets, the global robotics market is expected to grow from $62.75 billion in 2020 to $74.1 billion by 2025, with motion control systems playing a pivotal role in this growth. Industrial motors are integral to robotic applications, providing the precision and control required for tasks ranging from assembly to material handling. These motors enable robots to execute intricate movements, enhancing efficiency and accuracy in industrial processes.

Furthermore, advancements in motor technology are driving innovations in automation. A study by Research and Markets indicates that the global electric motor market is anticipated to reach $151.83 billion by 2025, growing at a CAGR of 7.21% from 2020. Higher efficiency motors, such as brushless DC and servo motors, allow for smoother operation and energy savings, making them ideal for automated systems. Enhanced feedback mechanisms and control algorithms have transformed how motors interact with robotic systems, leading to remarkable improvements in responsiveness and adaptability. As industries continue to embrace automation, the synergy between electric motors and robotic systems will undoubtedly result in groundbreaking advancements across various sectors.

Real World Applications of Best Industrial Motors in Different Industries

Comparative Analysis of HVAC Motors: Performance Metrics in Energy Efficiency

In today's rapidly evolving industrial landscape, the role of HVAC motors has emerged as crucial for optimizing energy efficiency across various sectors. This comparative analysis focuses on performance metrics of these motors, particularly highlighting the advantages of Brushless DC (BLDC) motors. With their enhanced adaptive speed control mechanisms, driven by intelligent algorithms like fuzzy logic, BLDC motors not only improve electric vehicle performance but also contribute to energy savings in HVAC systems. Their ability to efficiently manage varying loads while minimizing energy wastage is pivotal to sustainable industrial practices.

Furthermore, the integration of advanced machine learning techniques and graph attention networks in HVAC optimization systems allows for more precise energy management. For instance, projects like the one in Shenzhen Qianhai Smart Community are pioneering the use of ensemble learning approaches to create intelligent systems that adapt real-time to environmental changes and operational demands. Such innovations not only bolster the efficiency of HVAC systems but also align with global sustainability goals, setting a benchmark for other industries to follow in the pursuit of greener technologies.

Real World Applications of Best Industrial Motors in Different Industries - Comparative Analysis of HVAC Motors: Performance Metrics in Energy Efficiency

| Industry | Motor Type | Power Rating (kW) | Efficiency (%) | Annual Energy Consumption (MWh) | Cost Savings ($) |

|---|---|---|---|---|---|

| Commercial HVAC | Permanent Split Capacitor (PSC) | 5 | 85 | 3000 | 600 |

| Industrial Refrigeration | Variable Frequency Drive (VFD) | 10 | 90 | 5000 | 1200 |

| Data Centers | Electronically Commutated (EC) | 7.5 | 95 | 4000 | 1000 |

| Healthcare Facilities | Synchronous | 3 | 92 | 2500 | 450 |

Evaluating the Impact of Industrial Motors on Renewable Energy Systems Performance

The integration of industrial motors in renewable energy systems is critical to enhancing performance and efficiency. According to a report by the International Energy Agency (IEA), the electrification of various sectors can lead to a 20% reduction in global CO2 emissions by 2040. This statistic underscores the importance of utilizing high-efficiency motors that not only reduce energy consumption but also align with sustainability goals. For instance, the adoption of Permanent Magnet Synchronous Motors (PMSMs) in wind turbines significantly improves energy conversion rates, which boosts overall system efficiency by up to 30% compared to conventional motors.

Moreover, the performance of solar energy systems has also improved with advancements in motor technology. A recent study by the National Renewable Energy Laboratory (NREL) indicated that high-performance motors in solar tracking systems could enhance energy capture by approximately 25%. By accurately adjusting the orientation of solar panels throughout the day, these motors ensure optimal exposure to sunlight. Consequently, the implementation of sophisticated industrial motors is not only transforming renewable energy infrastructure but also proving essential in achieving a sustainable energy future.

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top