2026 Best Ac Electric Motor Options for Efficiency and Performance?

In the quest for energy efficiency and performance, AC electric motors stand out as vital components in various applications. These motors provide a reliable and effective solution for industries ranging from manufacturing to renewable energy. Selecting the right AC electric motor can be complex, given the numerous options available.

While many manufacturers advertise their products, not all motors deliver on their promises. Users must carefully consider factors such as efficiency ratings and operational performance. A poorly chosen motor can lead to wasted energy and increased operational costs.

Understanding the nuances of AC electric motors is essential. Some options excel in high-torque applications, while others are designed for speed. Evaluating specific needs before making a decision is crucial. Mistakes can result in significant losses, urging us to analyze our choices critically.

Overview of AC Electric Motors and Their Importance in Modern Applications

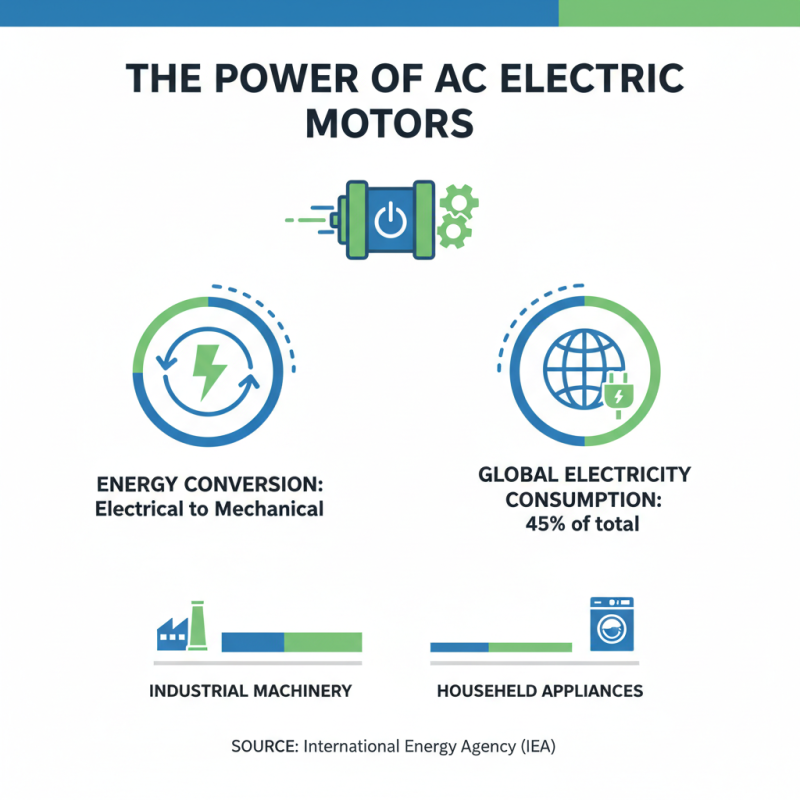

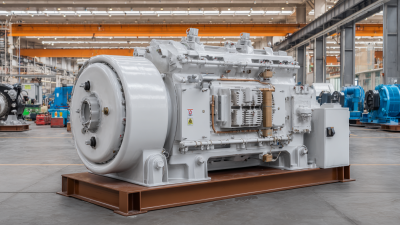

AC electric motors play a critical role in modern technology. They convert electrical energy into mechanical energy efficiently. According to the International Energy Agency (IEA), electric motors account for nearly 45% of global electricity consumption. This highlights their significance in various applications, from industrial machinery to household appliances.

The efficiency of AC electric motors varies widely. Some motors achieve an efficiency rating above 90%, while others fall short. Newer designs and materials can improve performance. However, many older systems struggle to keep pace. The U.S. Department of Energy reported that upgrading to more efficient motors can reduce energy consumption by 10-30%. This presents an opportunity for significant savings, both in costs and energy use.

Electric motors are also vital for sustainability goals. As industries aim to reduce carbon footprints, energy-efficient motors are a critical component. Data shows that optimizing motor systems reduces CO2 emissions. Yet, many facilities overlook motor maintenance. This neglect can lead to performance degradation. Regular checks and updates are necessary for maximum efficiency and lifespan. The need for conscientious upkeep remains a challenge in many sectors.

Key Factors Influencing Efficiency and Performance of AC Electric Motors

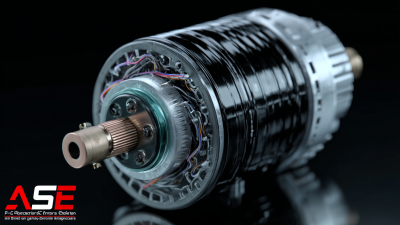

When selecting AC electric motors, various factors influence their efficiency and performance. The design of the motor plays a crucial role. A well-optimized design can minimize energy loss. Poor designs often lead to overheating and higher energy consumption. It’s essential to consider the core material, which impacts magnetic flux and overall efficiency.

Operating conditions also matter. Motors that are not suited for their environment may underperform. For instance, high humidity can cause deterioration, affecting longevity. Always assess the intended use before purchase. Ensuring proper ventilation and compatible settings can enhance performance.

Tips: Regular maintenance checks prevent potential issues. Schedule routine inspections to catch any wear early. Additionally, ensure the motor is matched to its application for optimal efficiency. Upgrading to a more modern design can yield significant performance gains.

Top AC Electric Motor Types Available in 2026: Features and Benefits

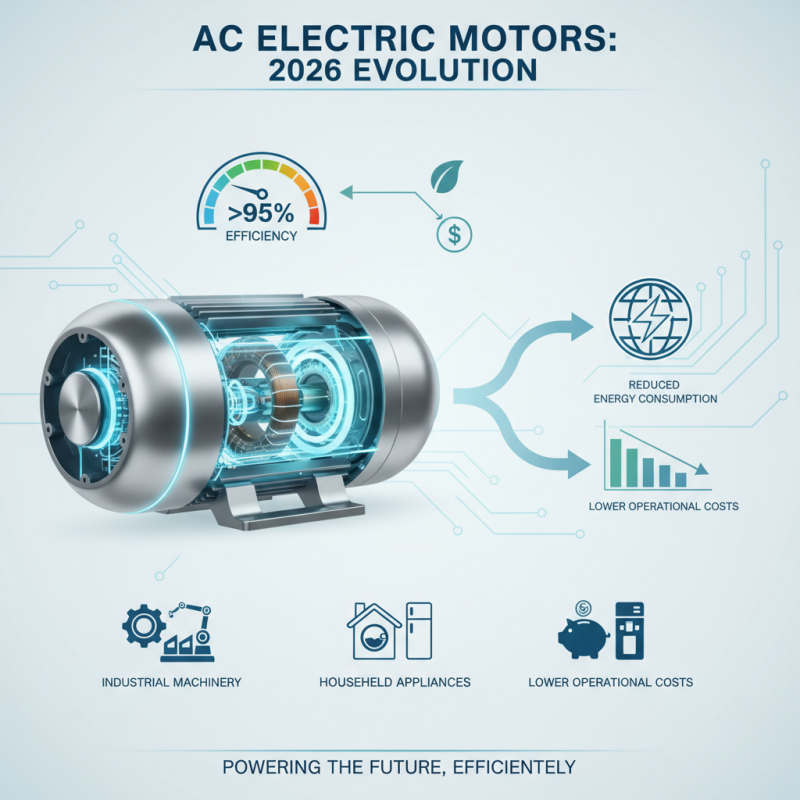

In 2026, AC electric motors have evolved significantly. They are essential in various applications, from industrial machinery to household appliances. The efficiency of these motors has improved, with many models achieving over 95% efficiency ratings. This contributes to reduced energy consumption and lower operational costs.

Different types of AC motors cater to specific needs. Induction motors are widely used due to their robustness and reliability. They require minimal maintenance and have a long operational life. Synchronous motors, on the other hand, offer precise speed control. They are ideal for applications requiring consistent and high-performance outputs.

However, not all options are perfect. Some users report challenges with torque performance in specific models. Additionally, while energy efficiency is critical, initial costs can be high. It’s essential to balance efficiency and upfront investment. Understanding specific application requirements is crucial in selecting the right motor. Engaging in research can help in making informed decisions that meet both efficiency and performance goals.

Comparative Analysis of Leading Brands and Models for Efficiency

AC electric motors play a vital role in various industrial applications. Efficiency is paramount in selecting the right motor. Some models can achieve efficiencies exceeding 95%. This is crucial for reducing energy costs. Models with high efficiency ratings often offer lower operational costs over time. However, not every brand meets performance expectations.

The choice of materials affects efficiency. Motors using advanced materials can reduce losses. Research shows that high-quality copper reduces resistance. Additionally, optimized designs enhance performance. However, poor manufacturing processes can lead to inefficiencies. It's essential to examine the specifications closely.

Tips: Regular maintenance is vital. Minor adjustments can improve efficiency. Keep an eye on the motor's operating temperature. Overheating can signal deeper issues. Consider environmental factors, too. Humidity and dust can impact performance. Always adapt your choice based on specific application needs. Approaching motor selection thoughtfully can save time and resources.

2026 Best Ac Electric Motor Options for Efficiency and Performance

| Model | Power Rating (HP) | Efficiency (%) | Starting Torque (lb-ft) | Weight (lbs) | Noise Level (dB) |

|---|---|---|---|---|---|

| Model A | 5 | 92 | 25 | 150 | 70 |

| Model B | 7.5 | 90 | 30 | 180 | 68 |

| Model C | 10 | 95 | 35 | 200 | 65 |

| Model D | 15 | 93 | 40 | 220 | 72 |

| Model E | 20 | 88 | 50 | 250 | 75 |

Future Trends in AC Electric Motor Technology and Innovations for 2026

As we look ahead to 2026, AC electric motor technology is evolving rapidly. Innovations focus on increasing efficiency and enhancing performance. For instance, improved materials, such as advanced magnets and lighter metals, are becoming more common. These enhancements can lead to significant energy savings. However, not all innovations are widely adopted. Some require further testing to prove their reliability.

Another trend is the integration of smart features. Motors equipped with Internet of Things (IoT) capabilities can communicate data in real-time. This offers insights into performance and maintenance needs. Yet, the complexity of these systems can pose challenges. Users may struggle with the technology and data interpretation.

Sustainability lessons also reshape AC electric motors. There is pressure to reduce waste and energy consumption. Many manufacturers aim for recycling components at the end of their life cycle. While promising, the actual implementation can be inconsistent. Companies must navigate cost versus environmental goals carefully. Balancing efficiency with eco-friendliness remains a significant task.

2026 Best AC Electric Motor Options for Efficiency and Performance

Related Posts

-

2025 Top 5 Single Phase AC Motors: Best Picks for Efficiency and Performance

-

Empowering Your Operations: Discovering Benefits of 3ph Electric Motors for Global Sourcing

-

Rising Above Tariff Challenges: How China's Best Electric Motor Manufacturers Thrive

-

The Future of Innovation in Best 3ph Electric Motor Technology

-

The Pride of China Delivering Best Break Electric Motors to the World

-

Exploring the Features and Applications of the Best Asynchronous Motor in Diverse Industries

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top