7 Excellent Benefits of Using Low Speed Motors for Your Business

In today’s rapidly evolving industrial landscape, the choice of motor technology plays a crucial role in optimizing operational efficiency and energy consumption. Low Speed Motors have emerged as a vital component for many businesses, offering not only cost savings but also enhanced performance across various applications. According to a recent report from the International Energy Agency, the adoption of energy-efficient motors, including Low Speed Motors, can reduce global electricity consumption by up to 30%, underscoring their potential for significant cost reductions and lower environmental impact. Furthermore, industry experts highlight that incorporating Low Speed Motors can lead to quieter operations and improved reliability, thereby minimizing maintenance costs and downtime. As businesses continuously seek innovative solutions to enhance productivity and sustainability, understanding the exemplary benefits of Low Speed Motors becomes essential for any forward-thinking organization.

Understanding Low Speed Motors: A Comprehensive Overview

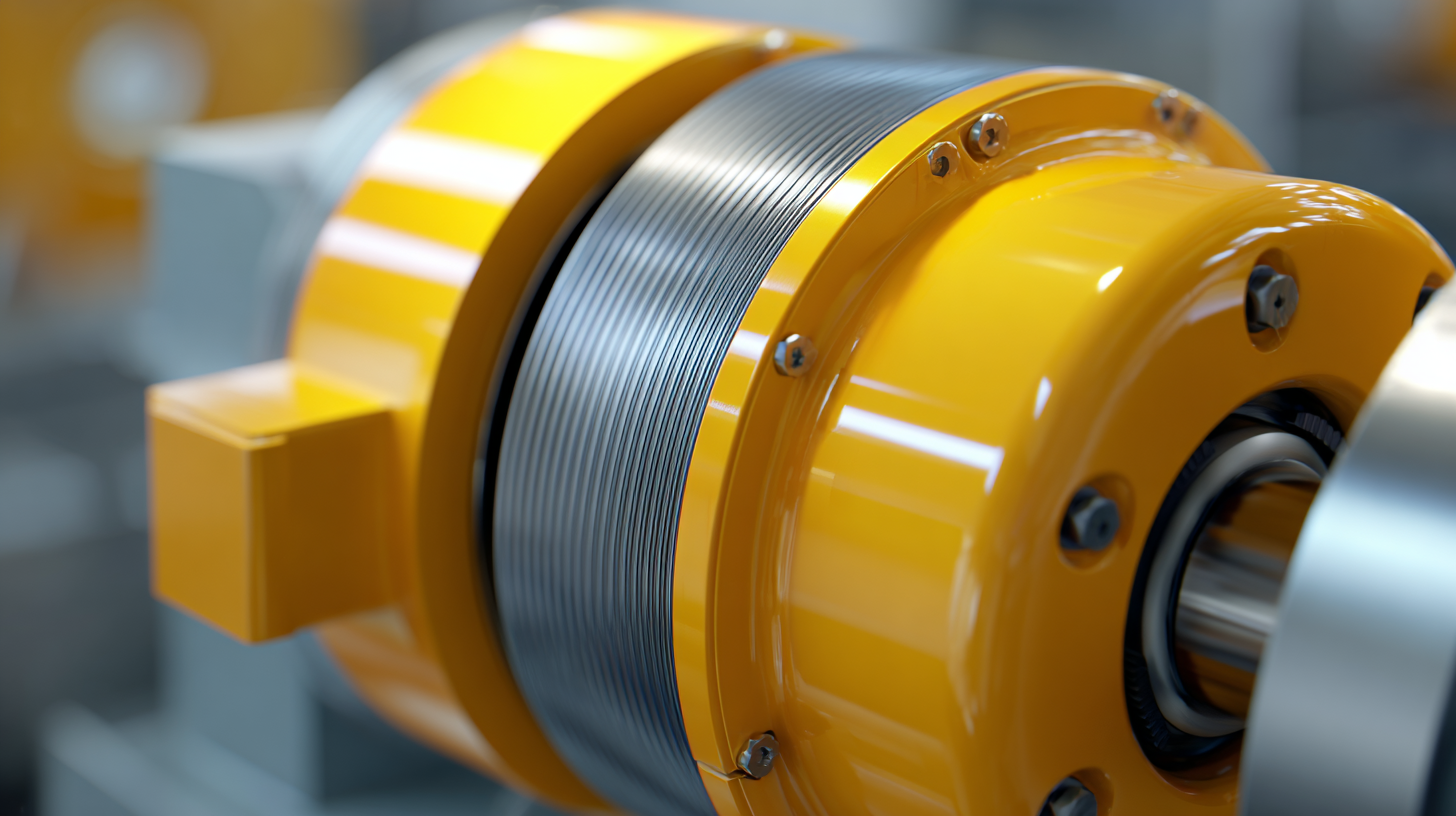

Low speed motors play a crucial role in various industrial applications, offering unique advantages that can enhance operational efficiency. Unlike their high-speed counterparts, low speed motors operate at lower revolutions per minute (RPM), making them ideal for tasks that require high torque and controlled motion. This characteristic allows businesses to achieve precise movements, which is particularly beneficial in industries like manufacturing, where accuracy is paramount.

Low speed motors play a crucial role in various industrial applications, offering unique advantages that can enhance operational efficiency. Unlike their high-speed counterparts, low speed motors operate at lower revolutions per minute (RPM), making them ideal for tasks that require high torque and controlled motion. This characteristic allows businesses to achieve precise movements, which is particularly beneficial in industries like manufacturing, where accuracy is paramount.

One of the key benefits of low speed motors is their energy efficiency. Operating at lower speeds often means reduced energy consumption, leading to cost savings over time. Additionally, these motors generate less heat, which can prolong their lifespan and minimize maintenance needs. Furthermore, low speed motors are typically quieter than high-speed motors, contributing to a more pleasant working environment. By utilizing low speed motors, businesses can not only improve their operational processes but also enhance employee satisfaction through reduced noise levels and increased safety in the workplace.

Key Advantages of Low Speed Motors for Energy Efficiency

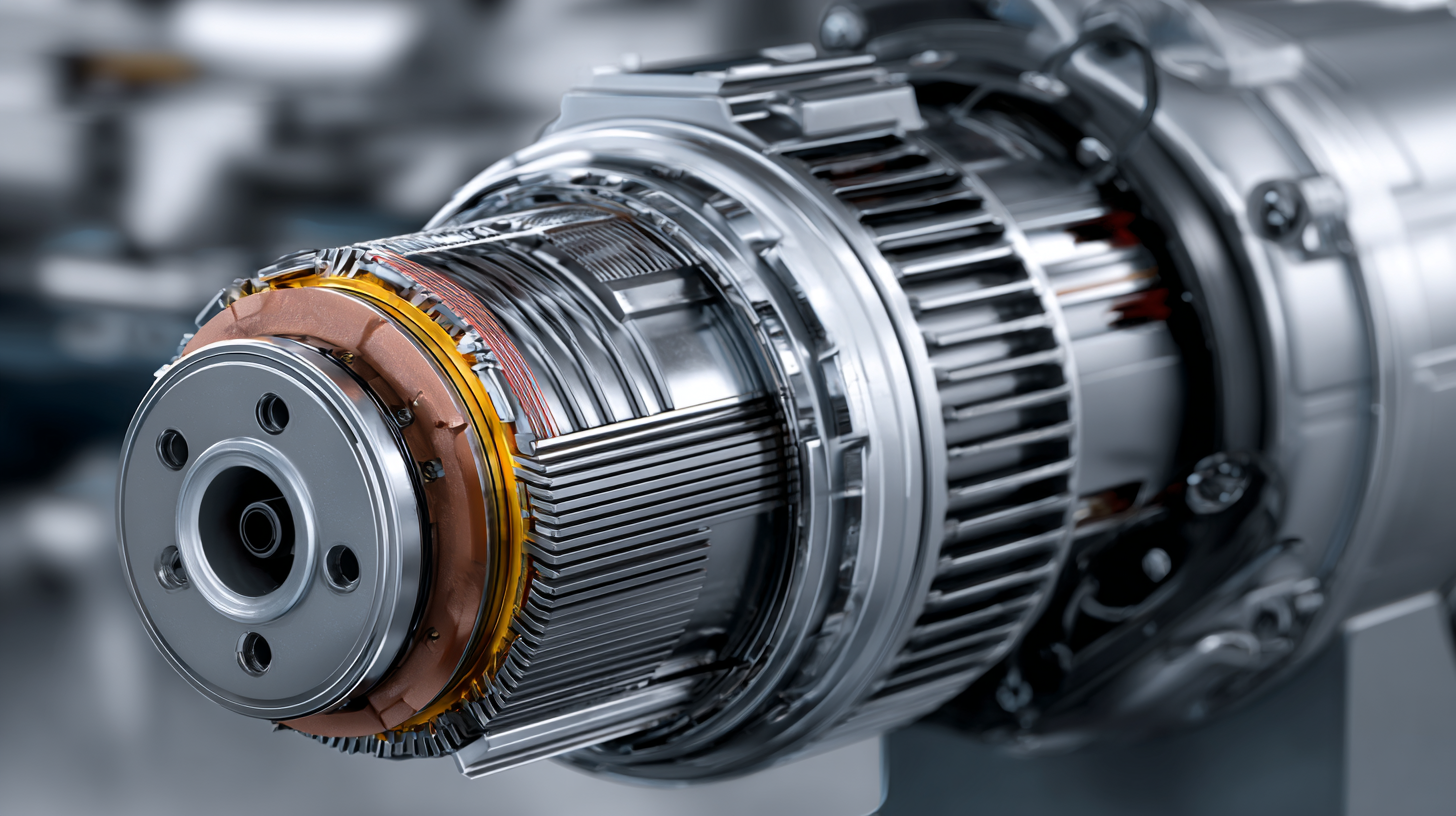

Low speed motors offer a range of key advantages that significantly enhance energy efficiency in various industrial applications. One of the primary benefits is their ability to operate effectively at lower speeds while still delivering optimal torque. This characteristic reduces mechanical stress on components and leads to decreased energy consumption, making them an ideal choice for operations that require sustained power over longer periods. Moreover, low speed motors often employ advanced design features that minimize energy loss due to friction and heat, further contributing to their efficiency.

Another notable advantage of low speed motors is their compatibility with modern control systems, allowing businesses to implement precise speed adjustments and better manage their energy use. This capability not only results in lower operational costs but also reduces the overall carbon footprint of industrial processes. Additionally, the durability and reliability of low speed motors mean less frequent maintenance and fewer replacements, which translates into both economic and environmental benefits. By integrating low speed motors into their operations, businesses can take a significant step towards achieving greater energy efficiency and sustainability.

Enhancing Product Longevity with Low Speed Motor Technology

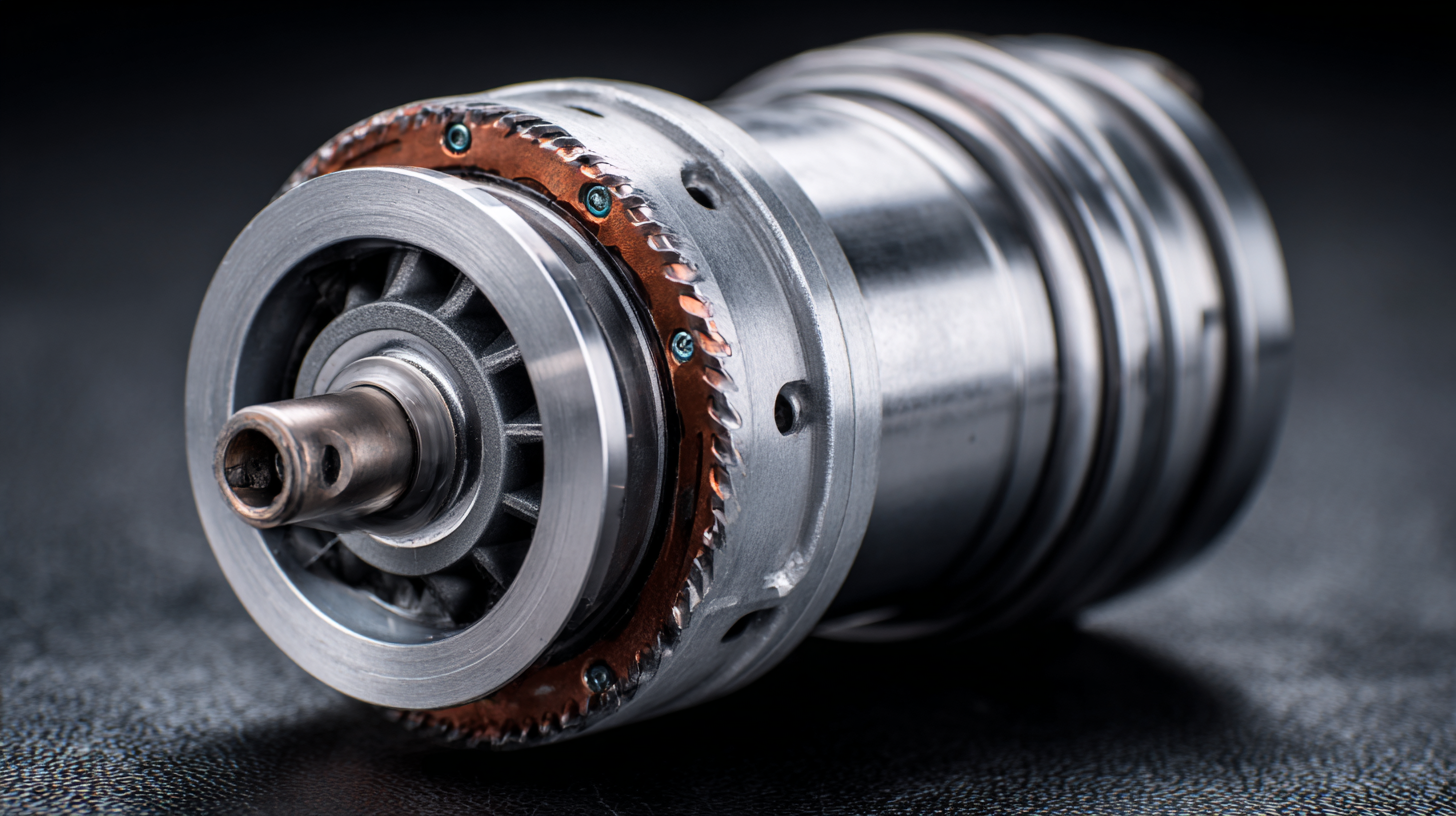

Low speed motors have gained significant traction in various industries owing to their ability to enhance product longevity. These motors operate at lower RPMs compared to their high-speed counterparts, which reduces wear and tear on mechanical components. According to a report by the International Journal of Engineering Research, equipment using low speed motors can experience a reduction in maintenance costs by up to 30%, due to decreased friction and heat generation. This not only extends the life of the machines but also improves overall operational efficiency.

When selecting low speed motors for your business, consider opting for models with advanced cooling systems. This can significantly mitigate overheating issues, which are common in conventional motors, thereby prolonging their lifespan. Additionally, investing in quality bearings and construction materials tailored for low-speed applications can further enhance reliability.

Tip: Regularly inspect and maintain your low speed motors by checking lubrication levels and alignment. Preventative maintenance can help avoid unforeseen downtimes and ensure your equipment operates at peak performance. By embracing low speed motor technology, businesses can not only reduce costs over time but also contribute to more sustainable operations by minimizing resource use and waste.

7 Excellent Benefits of Using Low Speed Motors for Your Business - Enhancing Product Longevity with Low Speed Motor Technology

| Benefit | Description | Impact on Longevity | Typical Applications |

|---|---|---|---|

| Reduced Wear and Tear | Low speed motors operate at a lower RPM, minimizing mechanical stress. | Increases lifespan of components by reducing friction. | Conveyors, fans, and pumps. |

| Energy Efficiency | Typically more energy-efficient, leading to lower operational costs. | Less heat and wear, extending motor life. | Water treatment, HVAC systems. |

| Quieter Operation | Low speed reduces noise levels, creating a better working environment. | Less vibration and disturbance prolongs equipment life. | Industrial facilities, residential applications. |

| Improved Control | Better torque control at low speeds for handling delicate materials. | Reduces the risk of damage, extending product and motor life. | Textiles, food processing. |

| Heat Management | Lower operational speeds generate less heat, reducing cooling needs. | Minimizes thermal stress, enhancing durability. | Cooling towers, thermal process equipment. |

| Versatility | Ideal for various applications across multiple industries. | Long-lasting solutions adaptable to many uses. | Manufacturing, agriculture. |

| Lower Maintenance Costs | Reduced frequency of repairs and downtime due to lower wear rates. | Enhances longevity by maintaining operational integrity. | Mining, construction equipment. |

Cost-Effectiveness: How Low Speed Motors Save Your Business Money

Low-speed motors are increasingly recognized for their cost-effectiveness in various industrial applications. According to a recent report by the International Energy Agency (IEA), around 70% of industrial energy consumption in the manufacturing sector is attributed to motor systems. Utilizing low-speed motors can significantly reduce energy consumption, which translates directly into lower operational costs. A study by the Department of Energy indicates that by replacing standard high-speed motors with low-speed counterparts, companies can achieve energy savings of up to 30%. This reduction not only diminishes monthly utility bills but also contributes to a more sustainable operational model.

Low-speed motors are increasingly recognized for their cost-effectiveness in various industrial applications. According to a recent report by the International Energy Agency (IEA), around 70% of industrial energy consumption in the manufacturing sector is attributed to motor systems. Utilizing low-speed motors can significantly reduce energy consumption, which translates directly into lower operational costs. A study by the Department of Energy indicates that by replacing standard high-speed motors with low-speed counterparts, companies can achieve energy savings of up to 30%. This reduction not only diminishes monthly utility bills but also contributes to a more sustainable operational model.

Moreover, low-speed motors often have longer lifespans and require less maintenance compared to their high-speed counterparts. The reliability of these motors leads to fewer breakdowns and unplanned downtime, resulting in enhanced productivity. According to research published by the Electric Power Research Institute (EPRI), businesses that adopt low-speed motors can decrease maintenance costs by up to 25%. This reduction in operating expenses allows companies to allocate resources towards innovation and growth, ultimately improving their bottom line. The combination of energy efficiency and reduced maintenance expenses makes low-speed motors an attractive investment for any business looking to optimize its financial performance.

Applications of Low Speed Motors Across Various Industries

Low speed motors have gained substantial traction across various industries due to their efficiency and versatility. According to a report by Allied Market Research, the global market for low-speed motors is projected to reach USD 19.56 billion by 2027, with an annual growth rate of 6.4%. This growth is driven primarily by their applications in sectors such as manufacturing, oil and gas, and renewable energy. In manufacturing, for instance, low-speed motors are essential for conveyor systems and heavy machinery, offering enhanced performance while minimizing energy consumption.

In the oil and gas industry, low-speed motors play a crucial role in powering equipment like pumps and compressors. A study by MarketWatch indicates that low-speed engine technologies can improve overall efficiency by up to 15%, leading to significant cost savings in production processes. Additionally, low-speed motors are increasingly utilized in renewable energy applications, particularly in wind turbines and hydroelectric systems, where they offer reliable power generation with lower environmental impact. As industries seek sustainable and cost-effective solutions, the adoption of low-speed motors is expected to continue to rise, reshaping the future of industrial operations.

7 Excellent Benefits of Using Low Speed Motors for Your Business

Related Posts

-

Discover Premium Low Speed Motors Directly from China's Leading Manufacturing Factory

-

A Comprehensive Comparison of Low Speed Motors Versus High Speed Motors

-

Top Strategies for Sourcing the Best Low Speed Motor Innovatively and Cost Effectively

-

Top 10 Low Speed Motor Manufacturers from China at the 137th Canton Fair

-

Unmatched Excellence in Chinese Manufacturing Leading the Global RV Gearbox Export Market

-

5 Essential Tips for Choosing the Right Gearbox Motor for Your Application

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top