How to Choose the Right Frequency Converter for Your Industrial Needs

In today's industrial landscape, optimizing equipment performance and enhancing energy efficiency are paramount, making the choice of the right Frequency Converter critical for operational success. According to a report by MarketsandMarkets, the global frequency converter market is projected to grow from USD 4.1 billion in 2020 to USD 5.6 billion by 2025, at a CAGR of 6.6%. This growth underscores the increasing reliance on frequency converters to regulate motor speed and improve energy consumption across various applications.

As industries seek to reduce costs while maximizing output, understanding the technical specifications and operational requirements of frequency converters is essential. Factors such as power ratings, input/output voltage, and harmonic distortion must be meticulously evaluated to ensure the selected frequency converter aligns with specific industrial needs and standards. Thus, making an informed decision in choosing a frequency converter can lead to enhanced productivity and significant cost savings in the long run.

As industries seek to reduce costs while maximizing output, understanding the technical specifications and operational requirements of frequency converters is essential. Factors such as power ratings, input/output voltage, and harmonic distortion must be meticulously evaluated to ensure the selected frequency converter aligns with specific industrial needs and standards. Thus, making an informed decision in choosing a frequency converter can lead to enhanced productivity and significant cost savings in the long run.

Understanding Your Industrial Power Requirements

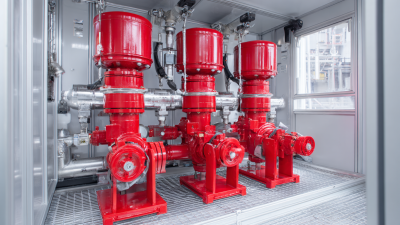

Understanding your industrial power requirements is crucial when selecting the right frequency converter. The first step involves analyzing the specific electrical demands of your machinery and equipment. This includes the voltage, current, and power factor needed for optimal operation.

Additionally, understanding the operational environment, such as temperature and humidity levels, can impact the performance and efficiency of the frequency converter.

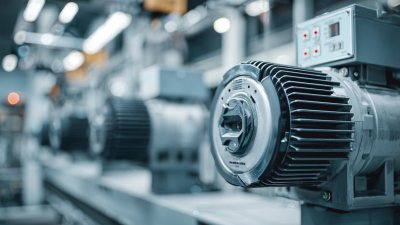

Another important aspect is to consider the type of loads being driven by the converter. Inductive loads, such as motors, may require a different approach compared to resistive loads. Identifying whether the application demands constant torque, variable torque, or special requirements like regenerative braking will influence your choice.

Furthermore, evaluating future scalability and potential expansions in your operations can guide you toward selecting a frequency converter that not only meets current needs but also adapts to future demands without requiring a complete re-evaluation.

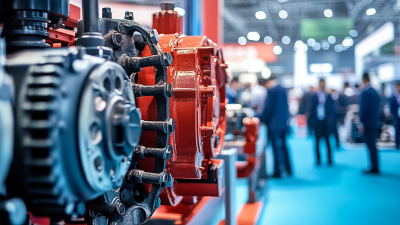

Types of Frequency Converters and Their Applications

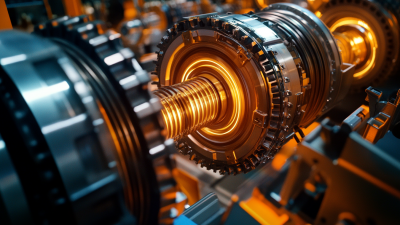

Frequency converters, also known as variable frequency drives (VFDs), are essential in industrial applications for controlling the speed and torque of electric motors. They come in various types, each suited for specific applications. The most common types include rotary converters, static converters, and digital frequency converters.

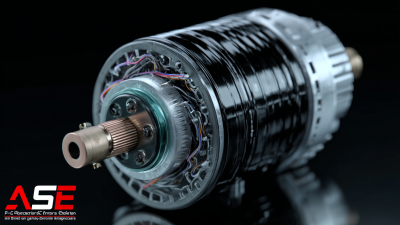

Rotary converters, which combine mechanical and electrical systems, are often used in larger industrial setups for their ability to handle high power levels. On the other hand, static converters utilize electronic circuits, making them more efficient and compact, suitable for smaller operations.

Digital frequency converters offer advanced features such as precise speed control, energy efficiency, and integration with automation systems. These converters are ideal for applications requiring tight control over operations, such as in textile manufacturing or conveyor systems. By understanding the characteristics and applications of each type of frequency converter, businesses can effectively select the right device that aligns with their operational needs, ensuring optimal performance and energy savings in their processes.

Key Features to Look for in a Frequency Converter

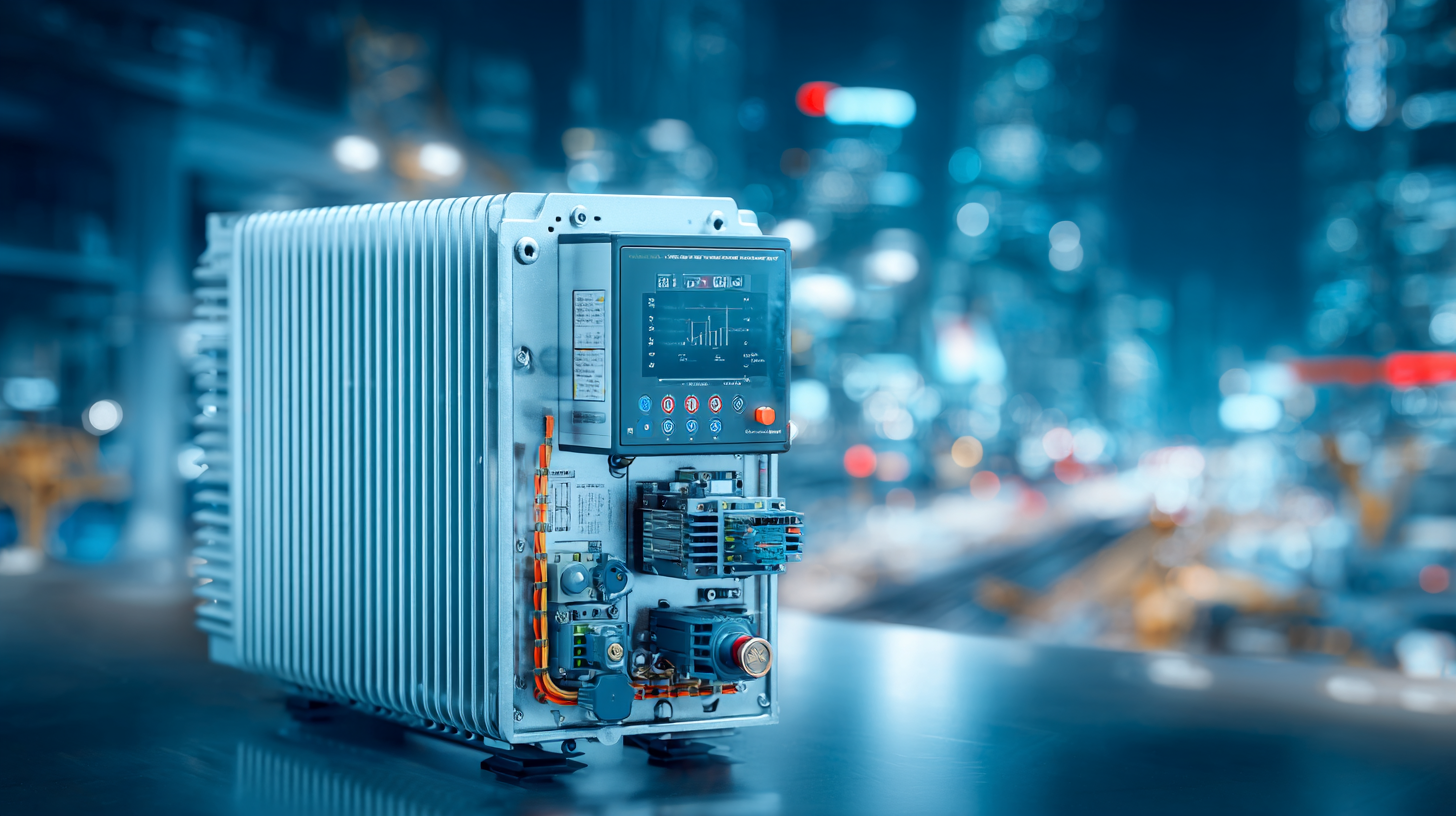

When selecting a frequency converter for industrial applications, it's essential to consider key features that directly impact performance and efficiency. First and foremost, the input voltage and power range of the converter must align with the electrical specifications of the motor and the overall system. This ensures optimal operation and reduces the risk of equipment damage. Additionally, the converter's output frequency range should accommodate the specific requirements of the machinery it will control, allowing for precise speed and torque adjustments.

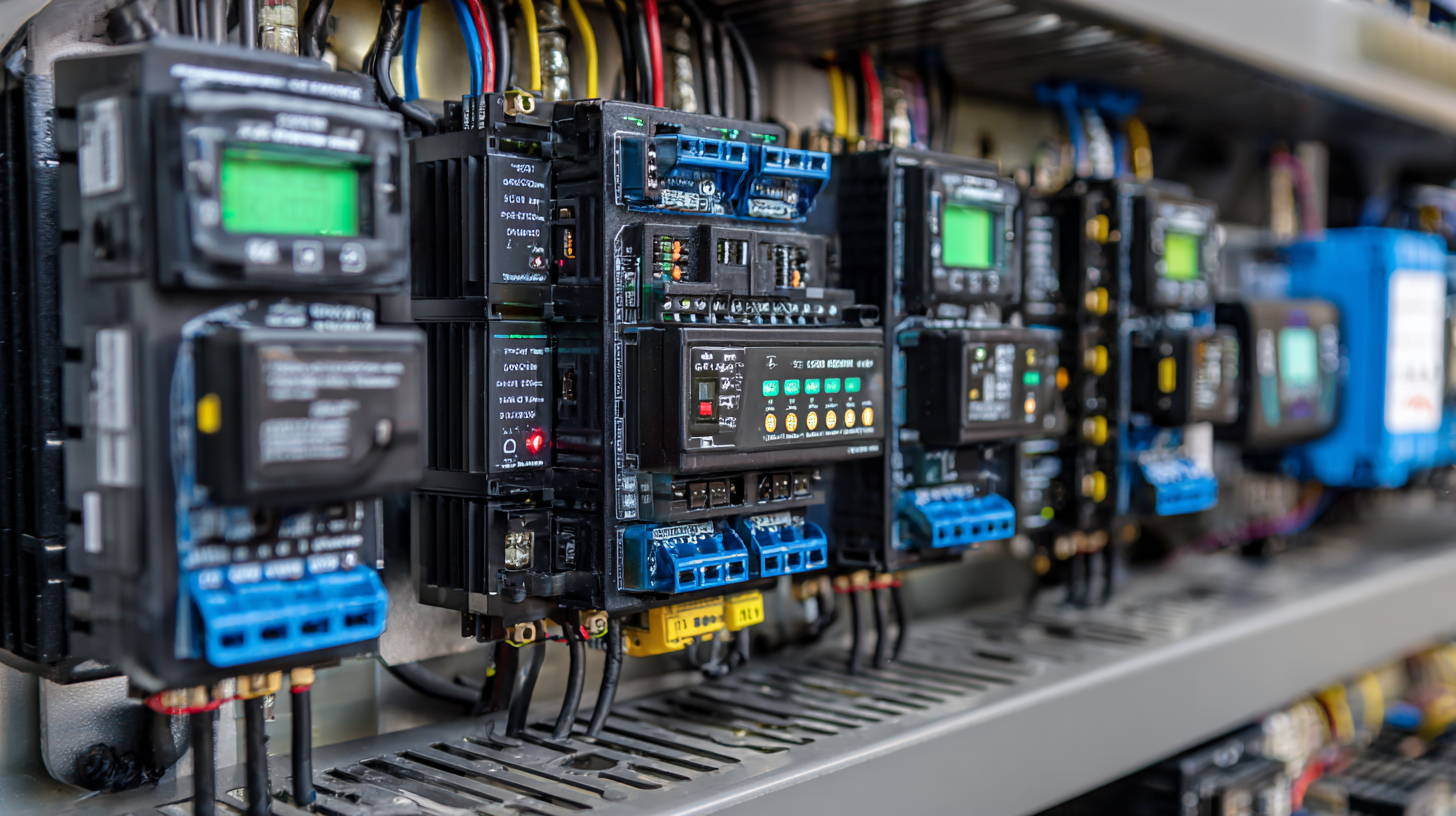

Another critical feature to examine is the converter's control mode. Options such as scalar control, vector control, or direct torque control can significantly influence the performance depending on the application. It's also important to evaluate the ease of installation and integration with existing systems, as well as the availability of programming software. Features such as built-in protection mechanisms, like overvoltage and overload protection, can enhance reliability and longevity of both the converter and the connected machinery. Thus, a well-considered selection based on these key features can lead to improved operational efficiency and reduced maintenance costs in industrial environments.

Evaluating Efficiency and Performance Metrics

When selecting the appropriate frequency converter for industrial applications, evaluating efficiency and performance metrics is crucial. Efficiency is often measured by how well the converter transforms input power to output power without excessive losses. High-efficiency converters operate at lower thermal levels, resulting in reduced energy consumption and longer operational life. It's essential to examine the converter's efficiency ratings, particularly under varying load conditions, as many converters perform differently at partial loads compared to full loads.

Performance metrics also play a significant role in choosing the right frequency converter. Key parameters to consider include output voltage stability, harmonics distortion, and response time. A converter that maintains a stable output voltage while managing load fluctuations enhances equipment lifespan and operational reliability. Additionally, low total harmonic distortion (THD) is essential to minimize adverse effects on motor performance and electrical systems. By analyzing these efficiency indicators and performance benchmarks, businesses can make informed decisions that align with their operational needs and energy-saving goals.

Considerations for Installation and Maintenance

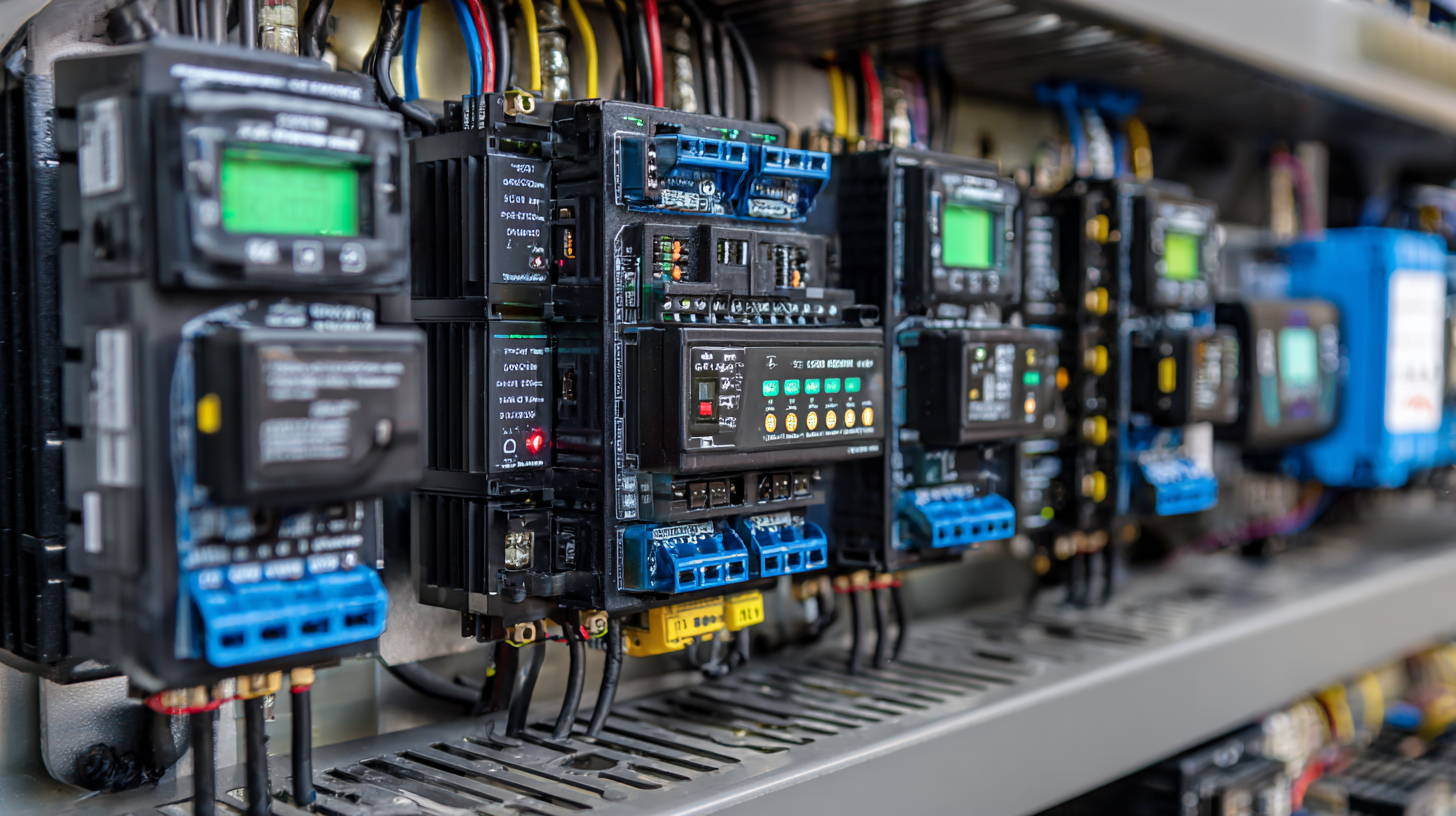

When selecting a frequency converter for industrial applications, careful consideration must be given to installation and maintenance aspects to ensure optimal performance. The installation process is critical as it involves integrating the converter with existing systems. Proper alignment of transformers, drives, and controllers is essential to avoid potential electrical issues. Additionally, ensuring adequate ventilation and spacing around the converter can prevent overheating and extend its lifespan.

Maintenance is equally important to keep the frequency converter operating efficiently. Regular inspections should focus on checking connections, cleaning dust accumulation, and testing for humidity levels that could affect performance. It is advisable to establish a routine maintenance schedule that includes updating firmware and monitoring operational metrics. By proactively addressing potential issues, industrial operations can minimize downtime and enhance reliability, ultimately leading to improved productivity.

As industries seek to reduce costs while maximizing output, understanding the technical specifications and operational requirements of frequency converters is essential. Factors such as power ratings, input/output voltage, and harmonic distortion must be meticulously evaluated to ensure the selected frequency converter aligns with specific industrial needs and standards. Thus, making an informed decision in choosing a frequency converter can lead to enhanced productivity and significant cost savings in the long run.

As industries seek to reduce costs while maximizing output, understanding the technical specifications and operational requirements of frequency converters is essential. Factors such as power ratings, input/output voltage, and harmonic distortion must be meticulously evaluated to ensure the selected frequency converter aligns with specific industrial needs and standards. Thus, making an informed decision in choosing a frequency converter can lead to enhanced productivity and significant cost savings in the long run.