How to Choose the Right Frequency Converter for Your Industrial Needs

In today's rapidly evolving industrial landscape, selecting the appropriate Frequency Converter is crucial for optimizing operational efficiency and ensuring energy savings. According to a recent industry report by MarketsandMarkets, the global frequency converter market is anticipated to reach USD 6.78 billion by 2025, driven by the increasing demand for energy-efficient solutions in various sectors. Frequency converters play a vital role in adjusting the output frequency and voltage of electrical power, enabling machinery to operate at desired speeds and reducing wear on equipment. With the rise of automation and the Internet of Things (IoT), industries are increasingly relying on advanced frequency converters to enhance their processes and sustainability. Therefore, understanding the key factors and specifications of frequency converters is essential for making informed decisions that align with both current needs and future growth.

Understanding the Fundamentals: What is a Frequency Converter and Its Role in Industry

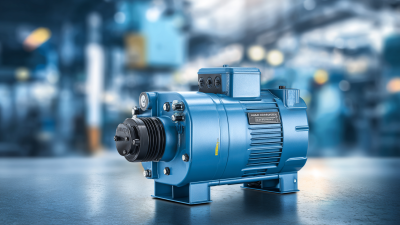

A frequency converter, also known as a variable frequency drive (VFD), is an essential device in various industrial applications, allowing for the control of motor speed and torque by adjusting the power frequency supplied to the motor. According to a report by MarketsandMarkets, the global VFD market is expected to reach USD 23.2 billion by 2026, driven by increasing energy efficiency policies and growing demand for automation. This device plays a critical role in enhancing the performance of equipment, reducing mechanical stress, and achieving significant energy savings, which are vital for maintaining competitive advantage.

In industrial settings, frequency converters facilitate the operation of electric motors across various sectors, including manufacturing, HVAC, and pumping systems. They adapt the supply frequency to meet specific operational demands, allowing for precise control over machinery. For instance, a study published by the International Energy Agency indicated that implementing VFDs can lead to energy savings of up to 50% in certain applications. As industries continue to prioritize sustainability and operational efficiency, understanding the fundamentals of frequency converters will become increasingly important for professionals aiming to optimize their processes and reduce operational costs.

Key Considerations in Choosing a Frequency Converter: Voltage, Power Ratings, and Phase Types

When selecting a frequency converter for industrial applications, understanding voltage is crucial. Frequency converters operate on different voltage levels, typically classified as low, medium, and high voltage systems. It is essential to match the converter's voltage rating with the power supply of your equipment to ensure compatibility and optimal performance.

Overestimating or underestimating the voltage can lead to equipment failure or inefficiencies, making voltage a primary consideration in the selection process.

Moreover, power ratings must be carefully assessed to ensure the frequency converter can handle the load requirements of your machinery. Power ratings, typically measured in kilowatts (kW) or horsepower (HP), should not only match the current demand but also provide a buffer for potential surges or increased loads in the future. This ensures longevity and reliability in operation.

Finally, the type of phase—single-phase or three-phase—plays a vital role in this decision-making process. The choice between these options affects the overall efficiency and performance of the application, hence understanding the specific needs of your system based on its operational requirements is essential for making an informed choice.

Matching Your Application: Selecting the Right Frequency Converter for Motors and Equipment

When selecting the right frequency converter for industrial motors and equipment,

it is crucial to consider the specific requirements of your application. Different motors operate under varying load

conditions and have unique operational needs that dictate the type of frequency converter required. For instance,

a dedicated converter with precise speed control may be essential for

applications requiring high accuracy, such as in CNC machinery, while a general-purpose converter might suffice

for less demanding tasks.

Moreover, understanding the operating environment and the type of equipment being used can also influence

your choice. Factors such as ambient temperature, humidity,

and the presence of dust or corrosive elements should be factored into

your selection process. Additionally, the power rating and the

motor type—whether it's an AC, DC, or servo motor—play a significant role

in determining compatibility with a frequency converter. Evaluating these parameters ensures seamless integration

and optimal performance of the system, ultimately enhancing productivity and efficiency in industrial operations.

Evaluating Efficiency and Performance Metrics: Understanding Harmonics and Energy Loss

When selecting the appropriate frequency converter for industrial applications, it’s crucial to evaluate efficiency and performance metrics, especially concerning harmonics and energy loss. Harmonics can significantly degrade power quality, leading to overheating and reduced operational lifespan of equipment.

Recent advancements in power electronics highlight the importance of integrating intelligent control systems, such as adaptive digital twins and artificial neural networks, which can optimize frequency converter performance and reduce energy losses. These technologies harness vast amounts of operational data to fine-tune converter functions, improving energy efficiency while managing harmonic distortion more effectively.

Moreover, research into optimal design configurations, such as multi-level inverters and AC-AC converters, reveals innovative methods for enhancing safety and performance in various industrial applications. By optimizing switching sequences and employing advanced algorithms, industries can fine-tune their systems to achieve better load management and efficiency. These improvements not only address current challenges in power quality but also support the increasing integration of renewable energy sources, facilitating a more resilient and efficient power distribution network.

Maintenance and Support: Ensuring Longevity and Reliability in Frequency Converter Systems

When selecting a frequency converter for industrial applications, maintenance and support play crucial roles in ensuring longevity and reliability. According to a report by MarketsandMarkets, the global frequency converter market is projected to reach USD 7.4 billion by 2025, emphasizing the growing dependence on these systems across various industries. Regular maintenance practices, including software updates and periodic inspections, can significantly reduce the likelihood of unexpected failures. Research shows that proactive maintenance can increase the lifespan of frequency converters by up to 30%, resulting in substantial cost savings on replacements and repairs.

Moreover, establishing a solid support system is vital for addressing operational issues quickly and efficiently. A study by the International Society of Automation highlights that nearly 70% of unplanned downtime in industrial operations can be traced back to inadequately maintained equipment. Partnering with manufacturers that offer comprehensive support, such as 24/7 technical assistance and readily available spare parts, can mitigate these risks. Ensuring that your frequency converter is backed by a robust maintenance and support plan not only enhances reliability but also optimizes overall performance in demanding industrial environments.

Related Posts

-

Empowering Global Industries: Quality Frequency Converters from China's Leading Manufacturers

-

How to Choose the Right Frequency Converter for Your Industrial Needs

-

Understanding the Mechanism Behind Variable Frequency Motors

-

A Comprehensive Comparison of Low Speed Motors Versus High Speed Motors

-

5 Effective Tips to Maximize Efficiency of Your Air Compressor for Optimal Performance

-

Challenges Faced by Global Buyers in Sourcing Aluminum Body Motors

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top