Exploring the Features and Applications of Best Variable Frequency Motors with Buying Tips

In today's rapidly evolving industrial landscape, the demand for energy-efficient solutions has led to the increasing popularity of Variable Frequency Motors (VFMs). These innovative motors offer unparalleled control over speed and torque, making them ideal for a wide range of applications including HVAC systems, conveyor belts, and water treatment facilities. However, selecting the right VFM involves navigating through various features and specifications, which can be daunting for many buyers. Moreover, finding a reliable supplier is crucial in ensuring that you invest in high-quality motors that meet your operational needs. In this blog, we will explore the essential features of the best Variable Frequency Motors, highlight their diverse applications, and provide valuable tips on how to identify and engage with reputable suppliers. Whether you're looking to upgrade your existing systems or implement new technologies, understanding these aspects will empower you to make informed decisions in your pursuit of efficiency and performance.

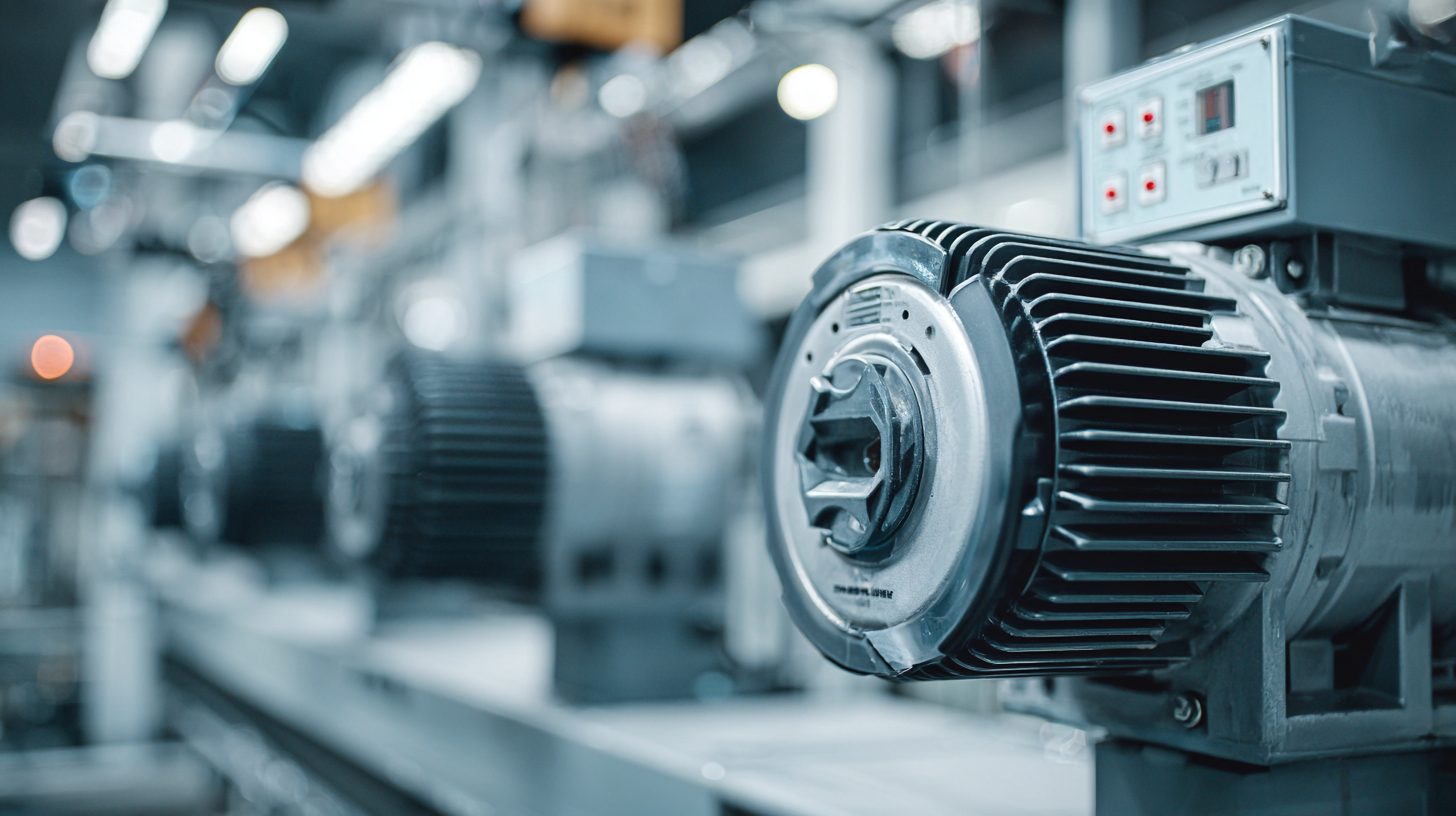

Understanding Variable Frequency Motors and Their Key Features

Variable Frequency Motors (VFMs) have gained significant traction in various industrial applications due to their energy efficiency and adaptability. By controlling the frequency and voltage supplied to the motor, VFMs can optimize performance based on operational needs. According to a report by Research and Markets, the global VFM market is expected to reach $20 billion by 2027, growing at a CAGR of 7.2%. This growth can be attributed to the increasing emphasis on energy savings and optimal performance in sectors such as manufacturing, HVAC, and renewable energy.

Key features of VFMs include precise speed control, reduced energy consumption, and extended equipment life. The ability to adjust speed without the need for additional gear mechanisms is particularly beneficial. According to a 2021 study from the U.S. Department of Energy, integrating variable frequency drives (VFDs) with electric motors can lead to energy savings of 30% to 50% in certain applications. Moreover, as industries move towards automation, VFMs provide enhanced control over machinery, leading to improved productivity and reduced downtime. These advantages make VFMs an indispensable component in modern industrial settings.

Applications of Variable Frequency Motors in Various Industries

Variable frequency motors (VFMs) play a crucial role across various industries due to their ability to efficiently control motor speed and minimize energy consumption. In sectors such as manufacturing, oil and gas, food and beverage, and pharmaceuticals, VFMs are widely utilized for applications that require precise speed regulation, such as pumps, fans, and conveyors. The integration of variable-speed intelligence into motors enhances their operational efficiency, allowing for real-time adjustments based on demand, which leads to substantial energy savings and improved performance.

When selecting a variable frequency motor, consider factors such as the specific application requirements, compatibility with existing systems, and energy efficiency ratings. Understanding the load characteristics and environmental conditions is also vital, as this will help in choosing the right motor with appropriate specifications. Additionally, pay attention to the support and service provided by the manufacturer, as reliable after-sales support can greatly impact long-term performance.

As the industrial motors market is anticipated to grow significantly in the coming years, investing in high-quality variable frequency motors can provide a competitive advantage. The adoption of advanced technologies, such as intelligent motors, is becoming increasingly prevalent, making it essential to stay updated on the latest innovations and trends within the market.

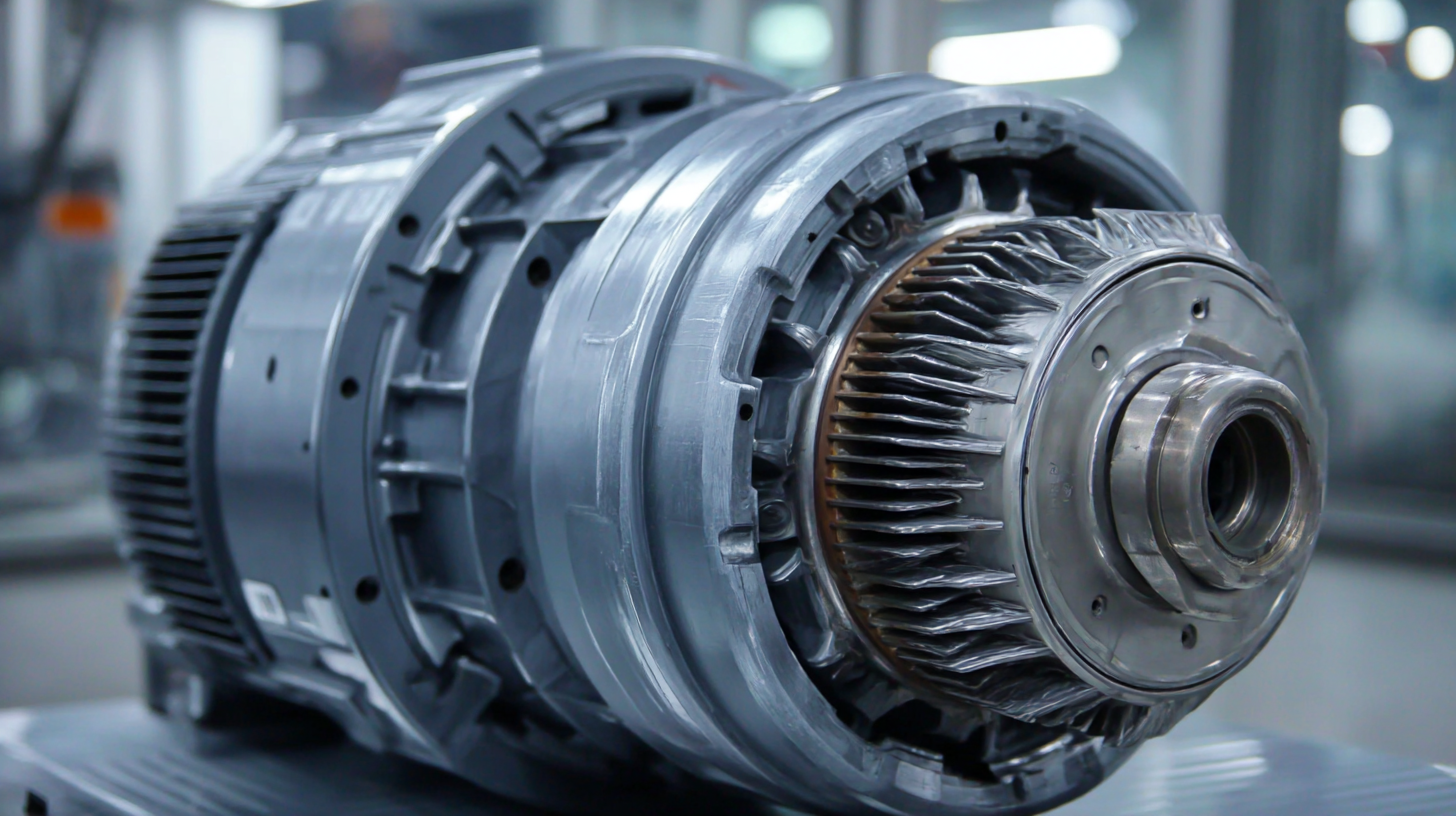

Factors to Consider When Choosing the Right Variable Frequency Motor

When selecting the right variable frequency motor (VFM), several critical factors come into play. First, understanding your application's power requirements is essential. Assess the starting and peak torque demands to ensure the VFM can handle the load efficiently. It’s vital to match the motor's specifications with the operational needs of your equipment to avoid performance issues.

Another crucial aspect to consider is the motor's operating environment. Factors such as temperature, humidity, and potential exposure to contaminants can influence the longevity and reliability of your VFM. For instance, if the motor will be used in a dusty or wet setting, opting for a motor with an appropriate IP rating can help ensure durability and consistent performance.

Tip: Always review the energy efficiency ratings of the motors you are considering. High-efficiency models may have a higher upfront cost but can lead to significant savings on energy bills over time, making them a wise investment for sustainable operations. Additionally, consider the availability of spare parts and service support to minimize downtime in case of maintenance needs.

Exploring the Features and Applications of Best Variable Frequency Motors with Buying Tips

| Feature | Description | Application | Power Range | Efficiency |

|---|---|---|---|---|

| Adaptive Control | Adjusts motor speed based on load demand | Conveyor Systems | 0.5 - 500 HP | Up to 95% |

| Variable Speed | Allows continuous adjustment of speed | Pumps and Fans | 1 - 1000 HP | Up to 98% |

| Energy Efficiency | Reduces energy consumption in operation | HVAC Systems | 0.75 - 750 HP | Up to 97% |

| Overload Protection | Prevents damage due to overload conditions | Industrial Machinery | 2 - 2000 HP | Up to 96% |

Buying Tips for High-Quality Variable Frequency Motors

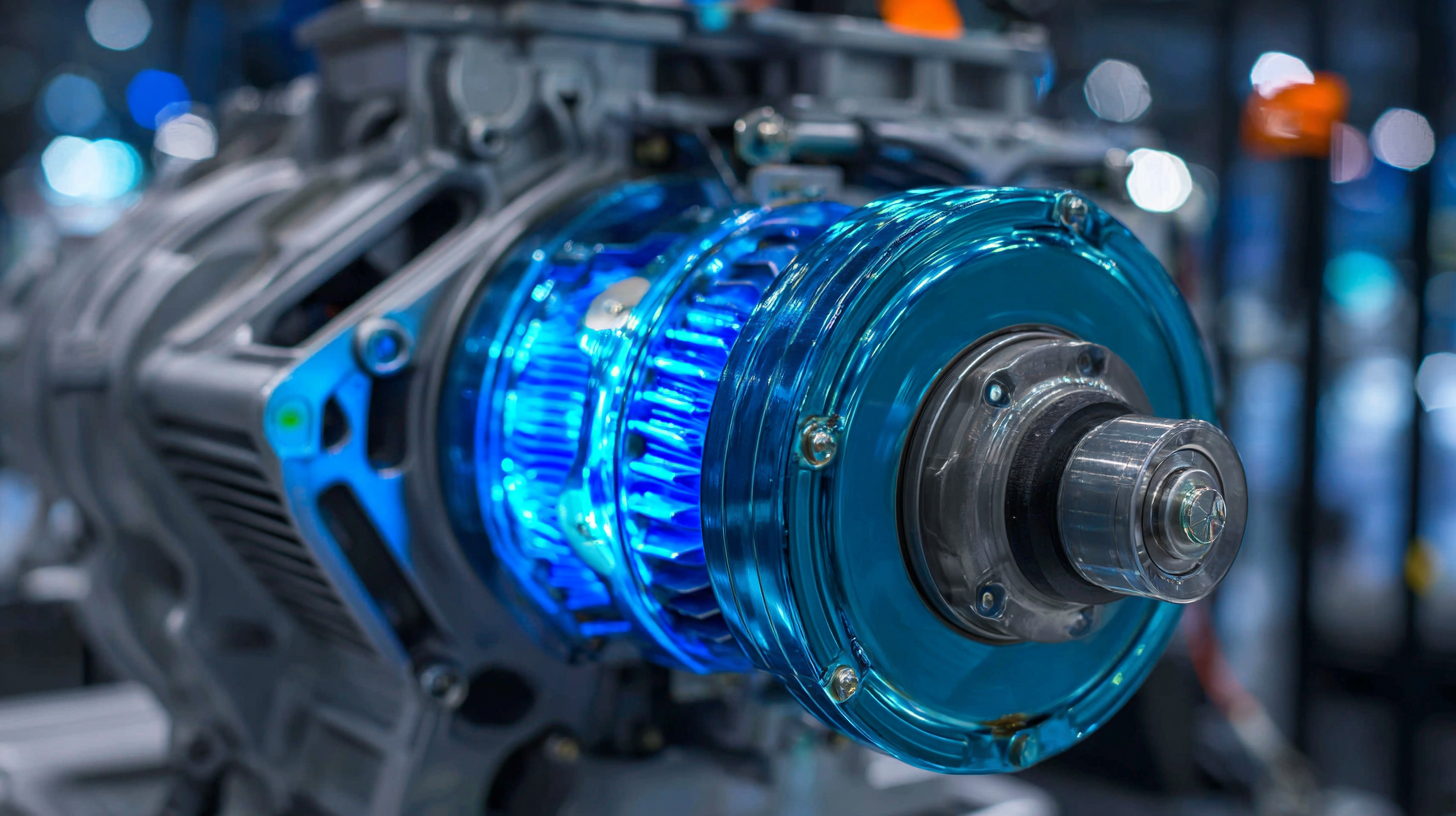

When considering the purchase of a variable frequency motor (VFM), it’s essential to focus on several key factors that influence both performance and durability. First, always look for motors that feature high-quality materials and construction. Motors built with premium components not only enhance efficiency but also extend the lifespan, ensuring reliable operation over time. Pay attention to the motor's insulation class, as this affects how well it can withstand heat generated during operation.

Another crucial factor is the motor's compatibility with your existing equipment. Before making a decision, assess the power requirements and operational settings of your application. This ensures that the variable frequency motor you choose can operate effectively within your system's parameters. Additionally, consider the motor's control features; advanced VFMs with better control algorithms can lead to improved energy savings and precise speed regulation, making them more suitable for complex applications.

Finally, don’t overlook the importance of after-sales support and warranty options. A reliable manufacturer will offer extensive customer support and a strong warranty, providing peace of mind should you encounter any issues. Researching user reviews and industry feedback can also guide you toward reputable brands known for their quality and service. By keeping these tips in mind, you can confidently select a high-quality variable frequency motor that meets your needs.

Industry Standards and Regulations Affecting Variable Frequency Motor Usage

The growing adoption of variable frequency drives (VFDs) across various industries is significantly influenced by industry standards and regulations focused on energy efficiency. The global VFD market is projected to grow from an estimated $24.68 billion in 2025 to approximately $32.00 billion by 2034, reflecting an increasing demand for energy-efficient motors and drives. With regulations pushing companies to minimize energy consumption and enhance operational efficiency, industries such as food and beverage, pharmaceuticals, and oil and gas are increasingly turning to advanced VFD solutions to meet these benchmarks.

Recent studies highlight the importance of adhering to these industry standards, as operating motors equipped with poor-frequency modulation techniques can lead to heightened losses compared to sinusoidal drives. For instance, experiments indicate that induction motors driven by PWM converters exhibit significantly higher losses, particularly under low load conditions. Consequently, manufacturers and users of variable frequency motors must remain aware of these standards to optimize performance and ensure compliance with current regulations, driving the ongoing evolution and innovation in VFD technology.

Features and Applications of Variable Frequency Motors

This bar chart illustrates the power ratings of various variable frequency motors (VFM) and their common applications in different industries. Understanding the features and application areas can help users make informed decisions while purchasing a VFM.

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top