Exploring Innovative Applications of Induction Motors Across Different Industries

In recent years, the induction motor has emerged as a cornerstone of modern industrial applications, driving efficiency and innovation across various sectors. Known for its robust design, reliability, and cost-effectiveness, the induction motor has proven to be an indispensable component in industries ranging from manufacturing and transportation to renewable energy and automation. As we explore innovative applications of induction motors, we uncover a wealth of solutions that not only enhance operational capabilities but also contribute to sustainability efforts by reducing energy consumption.

This blog aims to delve into the multifaceted roles of induction motors across different industries, showcasing how they are revolutionizing processes and paving the way for future advancements. Join us on this journey to discover the transformative impact of induction motors and the emerging technologies that are shaping their evolution.

Innovative Use Cases of Induction Motors in Renewable Energy Solutions

Induction motors have emerged as critical components in the renewable energy sector, notably in wind and solar power applications. According to the Global Wind Energy Council, wind power capacity reached over over 743 GW in 2020, with induction motors being integral to the operation of wind turbines. These motors facilitate the conversion of mechanical energy into electrical energy, enabling efficient energy generation. Moreover, the use of dual-fed induction motors in these turbines allows for variable-speed operation, which enhances energy capture and reduces mechanical stress, leading to improved performance and longevity of the systems.

In solar energy applications, induction motors play a vital role in tracking systems that optimize solar panel orientation towards the sun. A report by the International Renewable Energy Agency states that solar photovoltaics could account for up to 25% of global electricity generation by 2050. By employing advanced induction motor technologies in solar tracking mechanisms, efficiency can be significantly increased; studies indicate that solar panels with tracking systems can generate up to 40% more energy than fixed installations. The continued innovation and integration of induction motors in renewable energy solutions not only drive efficiency but also support the global transition towards sustainable energy sources.

Enhancing Manufacturing Efficiency with Induction Motors

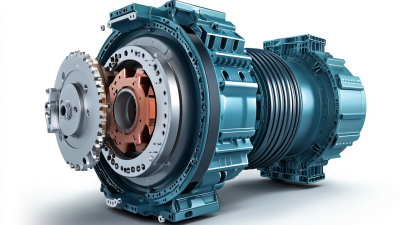

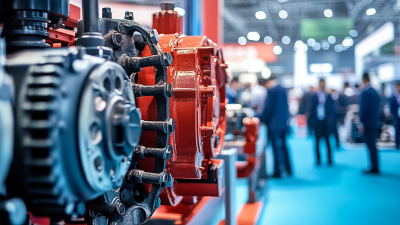

Induction motors have become indispensable in modern manufacturing, thanks to their efficiency, reliability, and adaptability across various applications. Their robust design allows for high performance and low maintenance, making them ideal for powering everything from conveyor systems to robotic arms. In industries such as automotive and food processing, induction motors contribute significantly to operational efficiency by ensuring consistent and precise movement, thereby reducing downtime and increasing productivity.

Induction motors have become indispensable in modern manufacturing, thanks to their efficiency, reliability, and adaptability across various applications. Their robust design allows for high performance and low maintenance, making them ideal for powering everything from conveyor systems to robotic arms. In industries such as automotive and food processing, induction motors contribute significantly to operational efficiency by ensuring consistent and precise movement, thereby reducing downtime and increasing productivity.

Moreover, the integration of smart technologies enhances the capabilities of induction motors. With the advent of IoT and advanced control systems, manufacturers can monitor motor performance in real-time, allowing for predictive maintenance and energy management. This not only minimizes operational costs but also promotes a sustainable approach to manufacturing. As industries continue to explore innovative applications for induction motors, their role in driving efficiency and productivity will only expand, paving the way for smarter manufacturing processes.

Revolutionizing Transportation: Induction Motors in Electric Vehicles

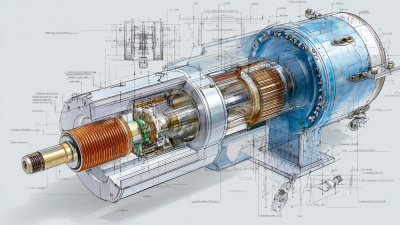

Electric vehicles (EVs) are at the forefront of the transportation revolution, and induction motors play a pivotal role in this shift towards sustainability and efficiency. Unlike traditional combustion engines, induction motors are praised for their high efficiency, reliability, and simplicity. These motors convert electrical energy into mechanical energy without the need for brushes, which reduces maintenance requirements and enhances the lifespan of the vehicle. Their ability to deliver high torque at various speeds makes them ideal for the dynamic demands of driving, enabling smooth acceleration and improved overall performance.

Moreover, the integration of induction motors in electric vehicles contributes to significant advancements in energy management. By utilizing advanced algorithms, these motors can optimize their performance according to driving conditions, improving energy consumption and extending battery life. This means that EVs equipped with induction motors can travel longer distances on a single charge, making them more appealing to consumers and reducing range anxiety. As the automotive industry continues to embrace this technology, we can expect a more sustainable and efficient transportation system that reduces our carbon footprint and enhances the quality of urban mobility.

Innovative Applications of Induction Motors in Electric Vehicles

This chart showcases the percentage distribution of induction motor applications across various sectors in electric vehicles, highlighting the importance of this technology in revolutionizing transportation.

Induction Motors in HVAC Systems: Improving Energy Management

Induction motors play a pivotal role in the energy management of HVAC systems,

enabling facilities to optimize their operational performance while minimizing

energy consumption. The integration of variable frequency drives (VFDs)

in induction motors allows for precise control of motor speed, resulting in

reduced energy use, lower peak demand, and enhanced comfort for building

occupants. By modulating the power supply, VFDs adjust the motor speed according

to real-time cooling and heating demands, making it possible for HVAC systems

to operate efficiently across various conditions.

As energy-efficient technologies gain momentum, the focus on high-efficiency induction motors

—rated under different efficiency levels (IE1, IE2, IE3, IE4, and IE5)—is increasingly important.

Facilities are now investing in these advanced motors to achieve compliance with energy regulations

while benefiting from lower operating costs. Furthermore, datasets like CLEMD provide

invaluable insights into circuit-level electricity consumption, facilitating research into effective

energy management strategies. By leveraging these innovations, industries can not only

enhance their energy management practices but also contribute to broader

sustainability goals.

Role of Induction Motors in Smart Appliances and Home Automation

Induction motors have become a cornerstone in the development of smart appliances and home automation systems. According to a report by Grand View Research, the global smart home market is expected to reach $174 billion by 2025, with smart appliances playing a pivotal role in this growth. Induction motors are integral to many of these devices, providing efficient and reliable performance in products such as washing machines, refrigerators, and HVAC systems. Their ability to operate efficiently under varying loads makes them ideal for smart home applications, where energy savings and optimal performance are key considerations.

Moreover, the integration of induction motors in home automation enhances user experience through automation and connectivity. A report from Research and Markets highlights that the adoption of IoT in home appliances is set to grow at a CAGR of 24% from 2020 to 2025. Induction motors' compatibility with smart technologies allows homeowners to control devices remotely, receive maintenance alerts, and even track energy consumption. This fusion of technology and mobility positions induction motors as vital components in creating energy-efficient and user-friendly home environments, transforming the way we interact with our surroundings.

Exploring Innovative Applications of Induction Motors Across Different Industries

| Application Area | Industry | Motor Type | Efficiency | Integration Level |

|---|---|---|---|---|

| Smart Washing Machines | Home Appliances | Single-phase Induction Motor | 85% | High |

| Automated Vacuum Cleaners | Smart Home | Brushless Induction Motor | 90% | Very High |

| Smart Refrigerators | Food Industry | Two-phase Induction Motor | 80% | Moderate |

| Smart HVAC Systems | Construction | Three-phase Induction Motor | 92% | High |

| Electric Gates | Building Automation | Asynchronous Induction Motor | 78% | Low |

Related Posts

-

Rising Above Tariff Challenges: How China's Best Electric Motor Manufacturers Thrive

-

The Pride of China Delivering Best Break Electric Motors to the World

-

Top Strategies for Sourcing the Best Low Speed Motor Innovatively and Cost Effectively

-

7 Compelling Reasons to Choose a Break Electric Motor for Your Machinery Needs

-

Unveiling the Specifications of the Best AC Electric Motor: A Comprehensive Technical Review

-

Top 10 Cast Iron Motor Manufacturers in China at the 137th Canton Fair

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top