Why Do You Need an Air Compressor for Your Projects?

An air compressor is essential for many projects, whether you are a DIY enthusiast or a professional. According to John Smith, an industry expert and founder of AirTech Solutions, "Air compressors are the backbone of efficient project execution." This sentiment rings true in various applications, from powering pneumatic tools to inflating tires.

Many people underestimate the versatility of an air compressor. Its ability to provide consistent power can save you time and effort. For instance, using an air compressor for spray painting ensures an even coat without the hassle of brushes or rollers. However, not all air compressors are created equal. The wrong choice can hinder your project's success.

Moreover, the maintenance of an air compressor is often overlooked. Regular checks and servicing are crucial for optimal performance. A neglected air compressor can lead to inefficiency, causing frustration in your work process. Reflecting on the need for an air compressor, it becomes clear that investing in the right one can greatly enhance productivity. Yet, many still find themselves confused or intimidated by the options available. This is an opportunity for learning and improvement in the industry.

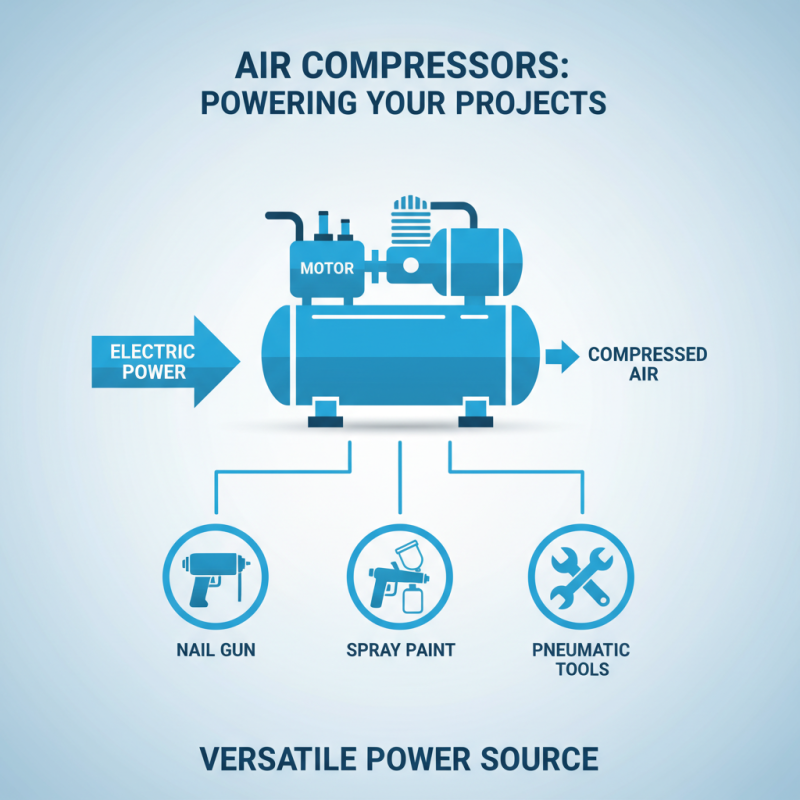

Understanding the Basics of Air Compressors and Their Functionality

Air compressors are essential tools in many projects. They convert electric power into compressed air. This process powers various devices. For instance, they can run nail guns, spray paints, and pneumatic tools. Their functionality is straightforward, yet versatile. Compressed air is stored in a tank and released as needed.

Understanding the workings of air compressors helps in selecting the right one. The size of the compressor matters. A small compressor may not handle heavy-duty tasks effectively. It’s crucial to consider the power requirements of your tools. Furthermore, regular maintenance is often overlooked. A poorly maintained compressor can lead to inefficiency and breakdowns.

It's interesting to note that not all projects require the same air pressure. Higher pressure is necessary for some tasks, while others may need less. This variability can be confusing. Choosing the wrong compressor can waste both time and resources. Experimentation may help in understanding the needs of specific projects. However, trial and error can lead to mistakes and frustration.

Key Applications of Air Compressors in Various Industries

Air compressors are vital in numerous industries. Their versatility makes them essential for a variety of tasks.

For example, in manufacturing, they power tools like nail guns and spray guns. This functionality helps streamline production.

Construction workers rely on compressors for pneumatic tools. These machines simplify heavy lifting and cutting tasks,

improving efficiency.

In the automotive industry, air compressors play a crucial role. They assist in painting vehicles and servicing tires.

A quick air boost can save time during maintenance. However, inefficiencies can arise. Without proper maintenance,

compressors may underperform, leading to delays.

In the medical field, air compressors provide oxygen and other gases for patients. They support critical operations in hospitals.

It’s important to ensure these machines are functioning correctly. The consequences of failure can be severe.

Each industry showcases the distinct applications of air compressors.

Their importance cannot be overstated.

Benefits of Using Air Compressors for DIY and Home Projects

Using an air compressor can elevate your DIY projects significantly. These versatile tools provide a reliable power source for various tasks. They can inflate tires, power nail guns, and even clean hard-to-reach areas. For home improvement, an air compressor boosts efficiency and saves time. Imagine finishing a painting job in half the time by using an air sprayer instead of a brush.

Let’s consider woodworking. An air compressor allows you to use pneumatic tools that simplify tasks like nailing and stapling. However, mastering these tools can take practice. Sometimes, they may not work as expected, leading to frustrating moments. It's essential to read instructions and understand how to maintain your equipment properly. Over time, you’ll learn to appreciate their benefits while also facing the occasional setback.

Air compressors also make cleanup easy. They can blow away debris from surfaces quickly. Yet, not every compressor is suitable for every project. Finding the right size and power output can be tricky. You might end up choosing one that feels inadequate later. Testing several types could prevent future inconveniences. Ultimately, integrating an air compressor into your routine can be rewarding, despite its challenges.

Why Do You Need an Air Compressor for Your Projects? - Benefits of Using Air Compressors for DIY and Home Projects

| Benefit | Description | Examples of Use |

|---|---|---|

| Increased Efficiency | Air compressors allow for quick and easy operation of tools, saving time on projects. | Spray painting, inflating tires |

| Versatility | Air compressors can power a variety of tools and equipment, making them suitable for many tasks. | Nail guns, air hammers, sanders |

| Improved Finish Quality | Tools powered by air compressors often provide a smoother finish compared to manual methods. | Spray painting walls, applying coatings |

| Cost-Effectiveness | Investing in an air compressor can reduce the cost of hiring professionals for certain tasks. | DIY home repairs, automotive work |

| Safety and Control | Using air compressors can reduce the risk of accidents associated with manual labor. | Power washing, air-cleaning surfaces |

How to Choose the Right Air Compressor for Your Needs

Choosing the right air compressor is essential for your projects. Not all compressors are created equal. Different applications require different types of compressors. You need to consider your specific needs before making a decision.

Look at the power source. Air compressors can be electric, gas, or battery-powered. According to industry reports, electric compressors dominate the market, accounting for over 70% of sales. They’re quieter and cleaner. Gas compressors are better for outdoor projects. Battery-powered options offer convenience for small tasks.

Next, think about pressure and volume. Your tool's requirements dictate these specs. For example, nail guns generally require 70-100 PSI. Conversely, spray guns may need over 30 PSI at higher CFM. Choosing the wrong compressor can lead to inefficiency. If it produces insufficient pressure, your tools won’t perform well. That results in wasted time and effort. Always check your tools' specifications before purchasing.

Maintenance Tips for Ensuring Longevity of Your Air Compressor

Maintaining your air compressor is crucial for its longevity. Regular oil checks and filter replacements can prevent major issues. Clean the air filter often to ensure smooth operation. A dirty filter can lead to reduced efficiency and unnecessary wear. Keeping the compressor in a clean, dry area also helps.

Pay attention to unusual noises. Strange sounds can indicate internal problems. Addressing these issues early on can save you time and money. Another important aspect is checking the hoses. Look for cracks or leaks regularly. Even small leaks can lead to significant air loss.

Don’t forget about proper storage. If you store your compressor improperly, it can lead to rust and other damage. Keep it in a cool, dry place. If you use it frequently, consider a dedicated space for it. It should be easily accessible. Taking these simple steps can ensure your compressor remains a reliable tool for your projects.

Related Posts

-

Exploring Air Compressor Innovations: Insights from the 138th Canton Fair 2025 in China

-

How to Choose the Right Air Compressor for Your Needs in 2025

-

The Ultimate Guide to Aluminum Motors Understanding Their Benefits and Applications in Modern Industry

-

How to Choose the Right Induction Motor for Your Industrial Applications

-

How to Choose the Right Centrifugal Pump Motor for Your Applications

-

Top 10 Induction Motor Types for Optimal Performance and Efficiency

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top