Quality Induction Motors Made in China Setting New Standards for Global Procurement

In today's global marketplace, the demand for high-quality Induction Motors is rising, prompting manufacturers to innovate and enhance their production standards. China has emerged as a significant player in this field, leading the charge with cutting-edge technology and rigorous quality control measures that set new benchmarks for global procurement. This blog explores the critical aspects of importing Induction Motors from China, emphasizing the importance of industry certifications and compliance with international standards. We will cover essential steps and best practices for businesses looking to source these motors effectively, ensuring they navigate the complexities of international logistics and quality assurance seamlessly. By understanding these dynamics, companies can unlock the potential benefits of Chinese-made Induction Motors while fostering a responsible and sustainable procurement strategy.

The Rise of Quality Induction Motors in China: An Overview

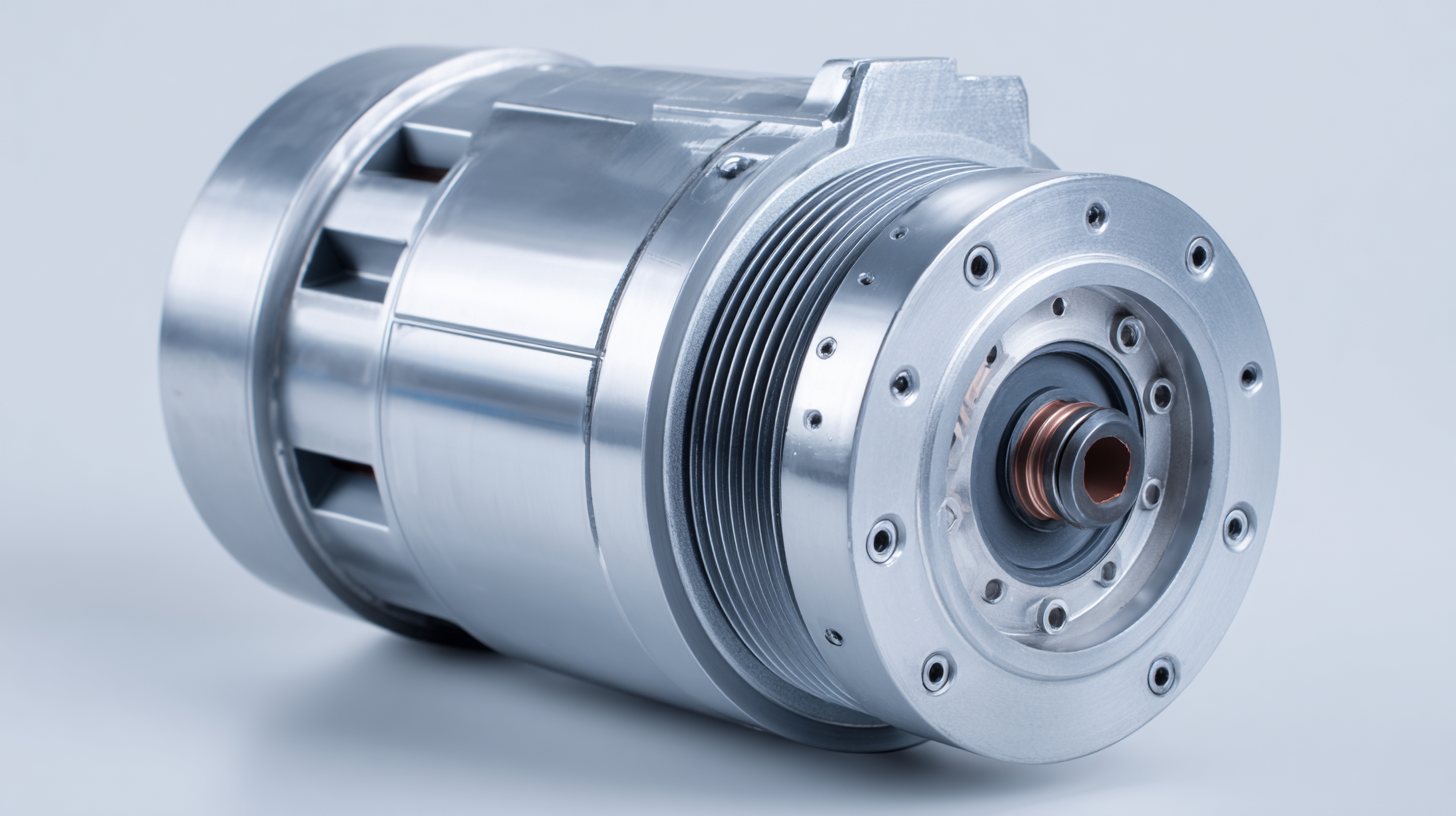

The resurgence of quality induction motors manufactured in China marks a pivotal shift in global procurement standards. With an enhanced focus on efficiency, recent studies have revealed innovative methods to mitigate power losses and improve cooling in electric machines. These advancements not only augment the performance of induction motors but also highlight China's commitment to elevating its manufacturing capabilities. As airgap eccentricity and electromagnetic performance are refined, the reliability and efficiency of these motors are set to rise significantly.

China's economic evolution has positioned it as a leading innovator in advanced industries. The growth in domestic innovation—from research in electric vehicle charging infrastructure to cutting-edge techniques in motor design—underscores the country's potential to redefine market dynamics. The development of state-of-the-art technology in universities and industries reflects a broader strategy to not only meet domestic demand but also to compete on an international scale. As these high-quality induction motors gain traction, businesses worldwide are likely to reconsider their procurement strategies, driven by the superior performance and reliability of Chinese products.

Key Technological Trends Shaping the Induction Motor Industry by 2025

The induction motor industry is on the brink of significant transformation, driven by key technological trends that are expected to shape the market landscape by 2025. According to a report by MarketsandMarkets, the global induction motor market is projected to grow from USD 22.5 billion in 2020 to USD 34.5 billion by 2025, highlighting a compounded annual growth rate (CAGR) of 9.1%. This growth is largely influenced by the rise of automation and the need for energy-efficient solutions in various industries.

One of the most prominent trends is the integration of smart technologies into induction motors. The adoption of the Internet of Things (IoT) allows for real-time monitoring and predictive maintenance, reducing downtime and maintenance costs. Research from Grand View Research indicates that the smart motor market alone is expected to reach USD 12.5 billion by 2025, driven by increasing demands for automated and remote-controlled systems. Furthermore, advancements in materials and manufacturing techniques are enhancing motor efficiency and lifespan, with steel and copper alloy innovations leading the charge.

Additionally, the push for sustainability is leading to the development of eco-friendly induction motors. The International Energy Agency (IEA) estimates that energy-efficient motors can reduce global energy consumption by up to 20%. In response, manufacturers are continuously investing in R&D to comply with stringent regulations while improving their products’ energy performance. With these technological advancements, induction motors made in China are not only meeting but setting new standards for quality and efficiency in the global market, paving the way for a greener and more intelligent industrial future.

How Chinese Manufacturers are Elevating Global Procurement Standards

Chinese manufacturers are making significant strides in the induction motor industry, setting new benchmarks for quality and efficiency in global procurement. According to a recent market analysis by Mordor Intelligence, the global industrial motor market is anticipated to reach USD 157.8 billion by 2025, with a CAGR of 6.4%. This growth is largely driven by the advancements in manufacturing techniques and the adoption of high-performance materials by Chinese companies. Notably, brands like Nidec and Siemens have acknowledged the improved performance specifications in Chinese products, which are increasingly meeting international standards.

Moreover, a study by Research and Markets indicates that the rise of Industry 4.0 necessitates the integration of smarter induction motors into production lines. Chinese manufacturers are responding to this demand by enhancing their product offerings with IoT capabilities and energy-efficient designs, making them more attractive to global buyers. As reported, energy-efficient motors can reduce energy consumption by up to 30%, significantly lowering operational costs for companies worldwide. The combination of competitive pricing and superior quality is enabling Chinese firms to set a new precedent, prompting global procurement strategies to evolve and adapt to these innovative offerings.

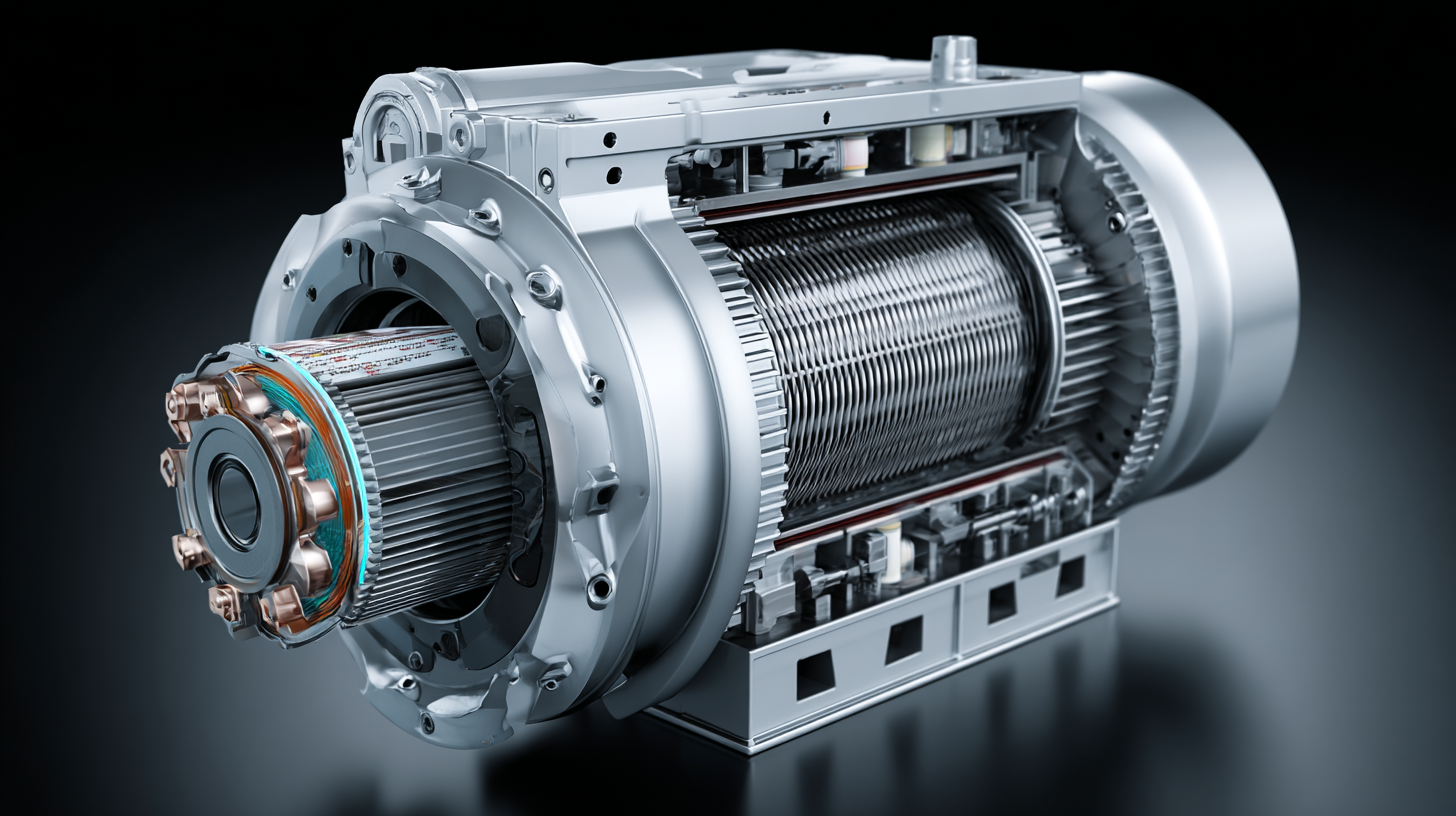

Innovative Designs and Engineering Practices in Induction Motors

Induction motors have long been a cornerstone in various industries, and Chinese manufacturers are now leading the charge by introducing innovative designs that emphasize efficiency and reliability. These motors are increasingly tailored to meet the diverse needs of global markets, showcasing advanced engineering practices that push the boundaries of traditional manufacturing. By integrating cutting-edge technology and materials, companies in China are revolutionizing the way induction motors are produced and utilized, ultimately setting new standards in global procurement.

Induction motors have long been a cornerstone in various industries, and Chinese manufacturers are now leading the charge by introducing innovative designs that emphasize efficiency and reliability. These motors are increasingly tailored to meet the diverse needs of global markets, showcasing advanced engineering practices that push the boundaries of traditional manufacturing. By integrating cutting-edge technology and materials, companies in China are revolutionizing the way induction motors are produced and utilized, ultimately setting new standards in global procurement.

Tip: When considering procurement options for induction motors, it’s essential to evaluate the technological advancements incorporated in the design. Look for manufacturers that prioritize energy efficiency and offer customizable solutions that align with your operational requirements.

Moreover, Chinese manufacturers are leveraging smart manufacturing techniques, such as AI and IoT, to enhance the performance and monitoring capabilities of their induction motors. These innovations not only ensure higher operational efficiency but also facilitate predictive maintenance, reducing downtime significantly.

Tip: Always inquire about the manufacturer’s commitment to innovation and R&D. A company that invests in the latest engineering practices is more likely to provide products that are not only reliable but also adaptable to future technological advancements.

The Future of Induction Motors: Sustainability and Efficiency in Focus

The future of induction motors is increasingly focused on sustainability and efficiency, aligning with global efforts to reduce energy consumption and lower carbon footprints. According to a report by the International Energy Agency (IEA), motor systems account for nearly 70% of industrial electricity consumption, highlighting the urgent need for optimizations. Chinese manufacturers are leading the charge with innovations in high-efficiency induction motors that not only comply with international standards but often exceed them. These advancements are crucial for industries aiming to enhance their energy efficiency, reduce operational costs, and minimize environmental impact.

Moreover, recent studies indicate that implementing more energy-efficient induction motors can lead to energy savings of 30% to 50%, depending on the application. The adoption of smart technologies, such as IoT-based monitoring systems, allows for real-time tracking of motor performance, paving the way for predictive maintenance and reduced downtime. As companies worldwide seek to modernize their operations and commit to sustainability goals, the procurement of quality induction motors made in China represents a strategic move towards achieving these objectives while ensuring reliability and performance.

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top