How to Select the Best Break Motor for Your Business Needs

In today's competitive industrial landscape, the selection of the right break motor is crucial for enhancing operational efficiency and ensuring safety in various applications. According to a recent report by MarketsandMarkets, the global electric motor market is expected to grow from $107.7 billion in 2020 to $174.9 billion by 2025, demonstrating a significant demand for effective drive systems, including break motors. Additionally, the increasing emphasis on energy-efficient solutions is prompting businesses to seek out motors that not only meet their specific performance needs but also contribute to overall energy savings. As industries navigate the challenges of automation and sustainability, understanding the key factors in selecting the best break motor becomes essential for optimizing performance and driving profitability. This guide will delve into critical considerations and expert tips to help businesses make informed decisions tailored to their unique operational requirements.

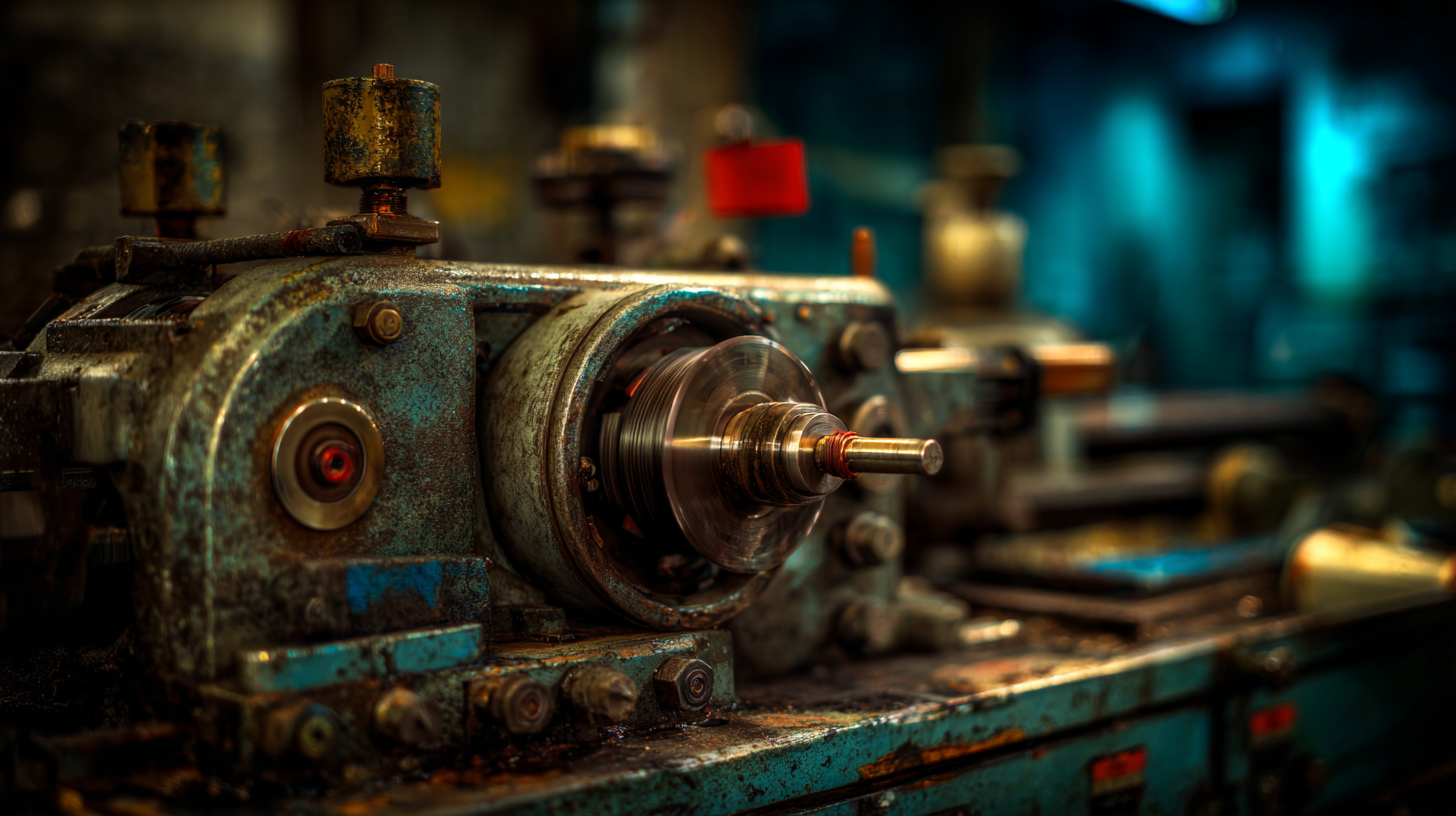

Understanding Break Motors: Types and Applications for Your Business

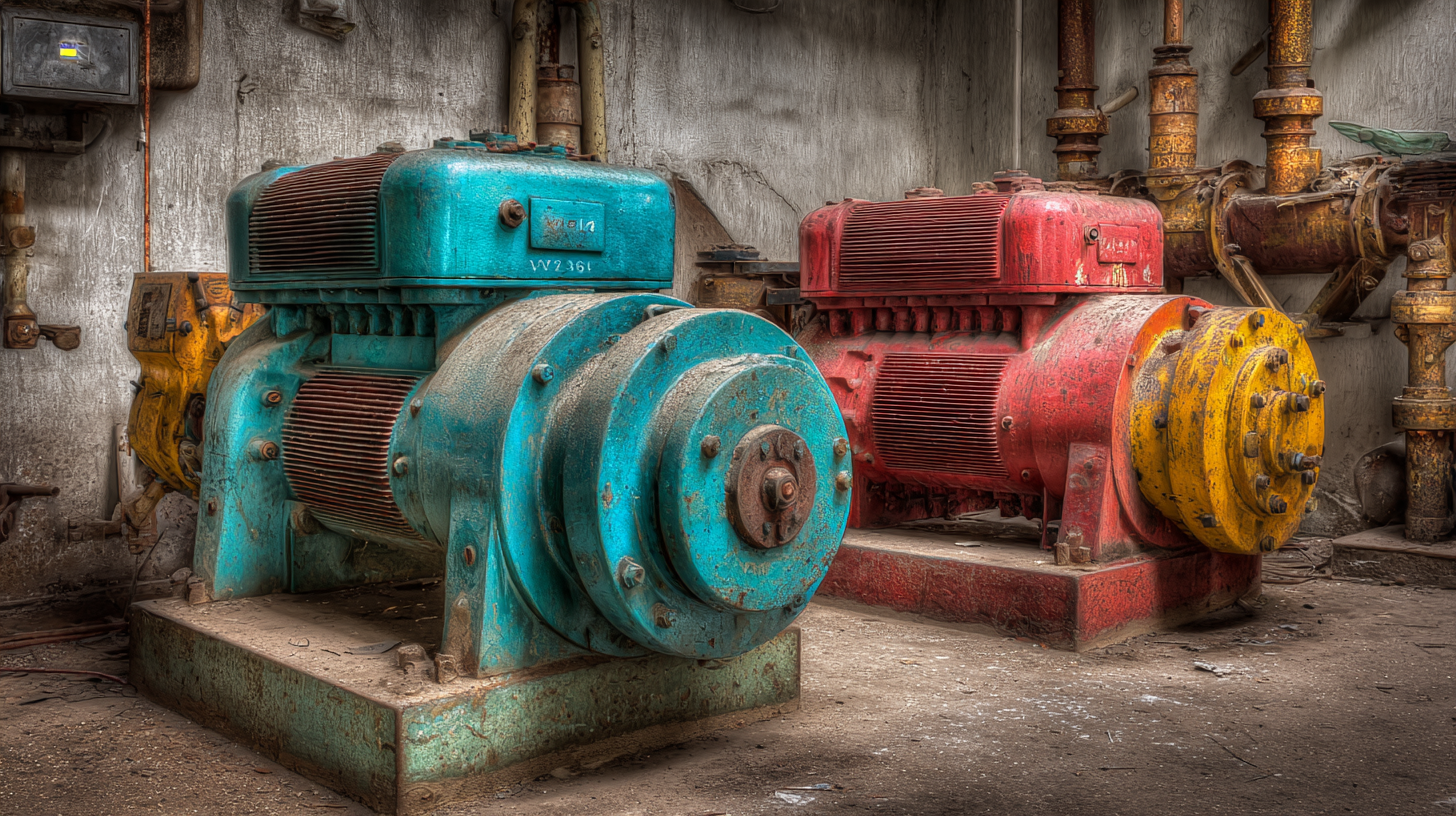

When selecting a break motor for your business needs, it’s essential to first understand the different types and their applications. Break motors can be broadly categorized into AC and DC types, with subcategories including synchronous and asynchronous motors. AC motors are often favored for their robustness and efficiency in continuous operations, while DC motors are popular for applications requiring variable speed control. Understanding these distinctions can help businesses align their motor selection with operational requirements.

Tips for selecting the right break motor include assessing the specific tasks the motor will perform. Consider factors such as load capacity, required torque, and the environment in which the motor will operate. It's also important to evaluate the compatibility of the motor with current systems and its maintenance needs. Additionally, with innovative advancements in technology, such as the development of motors that require no rare-earth elements, businesses have more options than ever to ensure sustainability and reduce reliance on scarce resources.

Another key point is to keep an eye on market trends, as the smart electric drive market is expected to grow substantially in the coming years. This growth is driven by the increasing need for efficient and environmentally friendly motor solutions. Staying informed on these trends can provide valuable insights into future-proofing your motor investments.

Key Factors to Consider When Choosing a Break Motor

When selecting a break motor for your business, understanding the key factors involved in the decision-making process is essential. First and foremost, consider the torque requirements of your application. The torque output must align with the specific demands of your machinery to ensure efficient operation. This means assessing the load conditions and the nature of the work the motor will be performing, whether it involves starting heavy loads or maintaining consistent power during operation.

Another critical aspect is the environment in which the motor will operate. Factors such as temperature, humidity, and potential exposure to hazardous materials can significantly influence the choice of the break motor. For instance, if your operation is in a damp or corrosive setting, selecting a motor with appropriate protective features, such as enclosures or coatings, is crucial. Additionally, evaluating the motor's duty cycle and expected lifespan will further guide your selection process, ensuring that the motor can handle the required workload without frequent maintenance or risk of failure.

How to Select the Best Break Motor for Your Business Needs

| Key Factor | Description | Importance Level |

|---|---|---|

| Power Rating | The motor’s power rating should match the application requirements to ensure efficiency. | High |

| Speed Control Options | Different applications may require varying speeds; hence options like variable speed drives are crucial. | Medium |

| Torque Output | The torque characteristics should meet the demands of the specific application. | High |

| Environment | Consideration of environmental factors such as temperature, humidity, and exposure to chemicals. | High |

| Size and Weight | The physical dimensions and weight of the motor affect installation and operational efficiency. | Medium |

| Energy Efficiency | Selecting an energy-efficient motor can significantly reduce operational costs over time. | High |

| Cost | Initial purchase cost versus long-term savings should be thoroughly evaluated. | Medium |

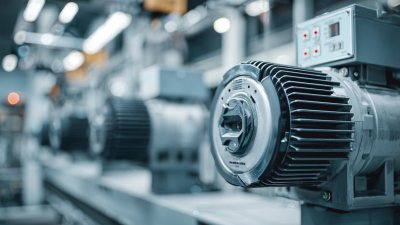

Comparing Break Motor Brands: Quality, Reliability, and Support

When selecting a break motor for your business, considering the brand is crucial. Different brands vary in quality, reliability, and customer support, which can significantly impact your operational efficiency. According to a recent report by the International Electromechanical Research Institute, around 30% of businesses experience downtime due to motor failures. This highlights the importance of choosing a dependable brand. Brands like Siemens and ABB consistently rank high for their durability and superior performance, with failure rates below 2% over five years.

Tip: Before making a purchase, assess the warranty and support services provided by the brand. A robust warranty policy can safeguard your investment and minimize operational disruption. Additionally, a brand known for excellent customer service can assist you in troubleshooting and maintenance, making a significant difference in your overall experience.

Furthermore, it’s essential to evaluate the long-term operational costs associated with different brands. A study by the Electrical Engineering Society indicates that premium brands may have higher upfront costs but offer lower energy consumption and better longevity, leading to lower total cost of ownership over time. This consideration is critical when selecting a break motor that aligns with your business needs and budget.

Tip: Conduct a life-cycle cost analysis for the break motors you are considering. This will help you identify not only the initial investment but also the ongoing operational costs, thereby facilitating a more informed decision.

Break Motor Brands Comparison: Quality and Reliability

This chart compares various break motor brands based on quality and reliability ratings. Each brand is evaluated on a scale from 1 to 10, where 10 represents the highest quality and reliability.

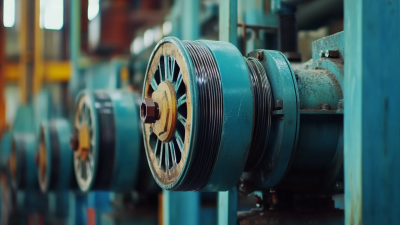

Sizing Your Break Motor: How to Determine the Right Specifications

Selecting the right break motor for your business needs is crucial, and sizing plays a significant role in determining the best specifications for your application. The first step in sizing your break motor is to assess the load requirements. This involves evaluating the heaviness of the load it will handle and the speed necessary for your operations. It's essential to calculate the torque requirements as well, since different applications demand varying levels of torque to function efficiently.

Tip: Gather detailed information about your operational environment, such as ambient temperature and potential exposure to elements, as these factors can impact motor performance. Also, consider the duty cycle of the motor, which defines how long it will run and at what frequency. This information is vital for ensuring that the motor you choose can perform reliably without overheating or failing prematurely.

Another critical aspect is to review the various features available in break motors. Look for options with adjustable speed control or integrated safety features that can enhance overall performance and safety in your operations. Selecting a motor with built-in diagnostics can also aid in maintenance, reducing downtime and improving productivity.

Cost vs. Value: Making an Informed Investment in Break Motors

When selecting the right break motor for your business, it's essential to weigh the cost against the value it brings. A commonly overlooked factor is that a higher upfront cost may translate into long-term savings through enhanced efficiency and reduced maintenance. Investing in a high-quality break motor that aligns with your operational demands can significantly impact productivity and reliability.

Tip: Always evaluate the total cost of ownership instead of just the initial purchase price. This includes factors like energy consumption, maintenance costs, and operational life expectancy. Consider energy-efficient models that, while potentially pricier, can yield substantial savings over time.

Another consideration is the importance of choosing the right specifications for your needs. Break motors come in various designs and configurations, tailored for specific applications. Thoroughly assess your operational requirements to ensure you select a motor that provides optimal performance without unnecessary features that inflate costs.

Tip: Consult with industry experts or manufacturers to gain insight into the most suitable options. Their experience can help you navigate the complexities of motor specifications and ensure you make an informed choice that balances cost and value effectively.

Related Posts

-

Solutions for Outstanding Performance in Asynchronous Motors

-

Challenges Faced by Global Buyers in Sourcing Aluminum Body Motors

-

Exploring the Features and Applications of Best Variable Frequency Motors with Buying Tips

-

How to Choose the Right Gear Reducer for Your Industrial Applications

-

Future Trends in the Best Iron Body Motor Market Towards 2025

-

Real World Applications of Best Industrial Motors in Different Industries

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top