Unveiling the Specifications of the Best AC Electric Motor: A Comprehensive Technical Review

In the rapidly evolving landscape of electrical engineering, the AC electric motor stands out as a critical component driving both efficiency and innovation. According to a recent report by MarketsandMarkets, the global AC motor market is projected to reach $33.9 billion by 2025, growing at a CAGR of 6.5% from 2020. This growth is fueled by increasing demand for energy-efficient technologies across various sectors, including automotive and manufacturing.

As we delve into a comprehensive technical review of the best AC electric motors available today, we will explore the vital specifications, performance benchmarks, and emerging trends that are shaping the industry's future. This analysis will not only highlight the technological advancements but also provide insights necessary for stakeholders looking to invest in or optimize AC electric motor systems.

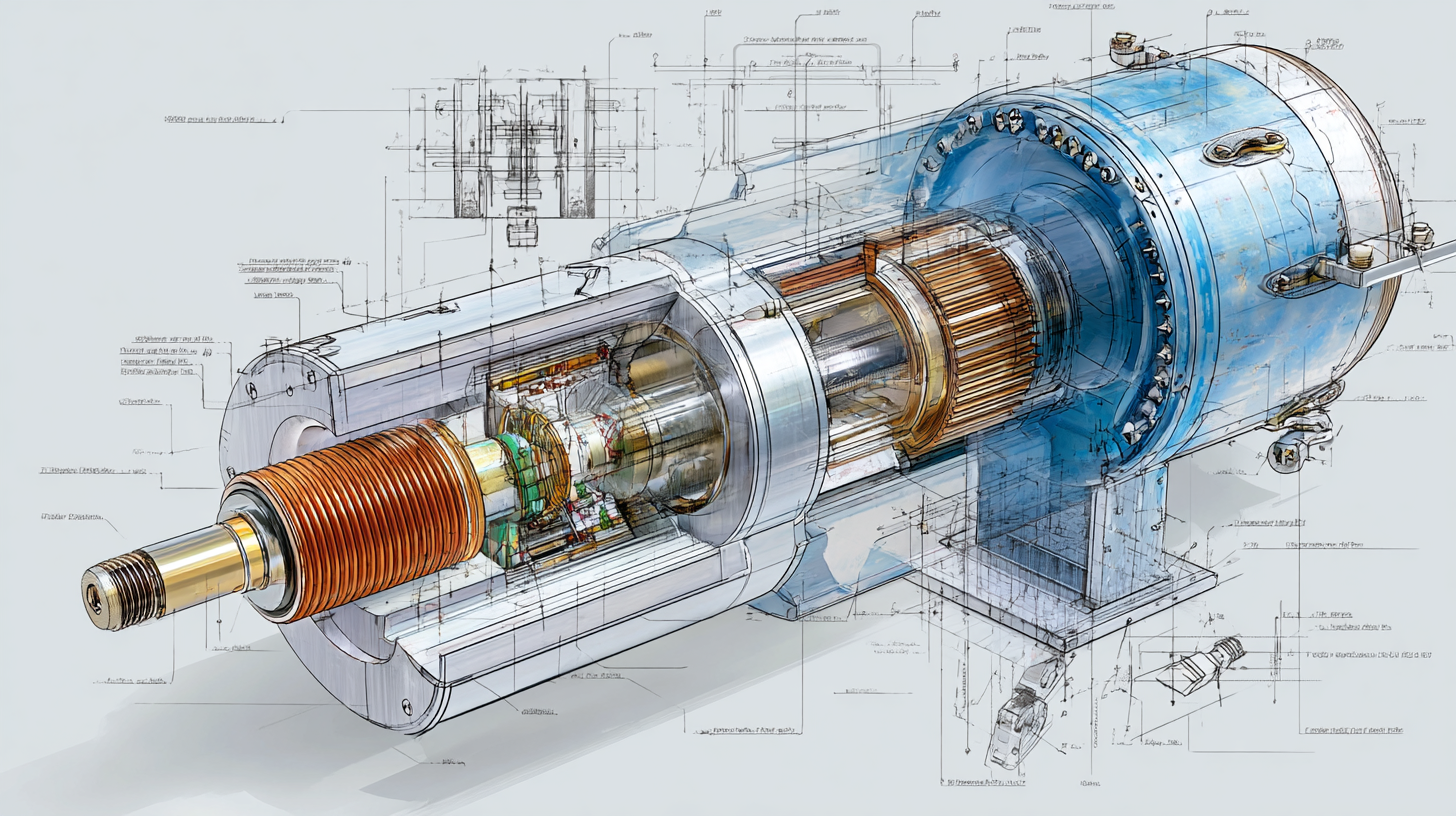

Understanding AC Electric Motors: Types and Applications

AC electric motors are vital components in various industries, providing efficiency and reliability for numerous applications. Understanding the types of AC motors is essential for selecting the right one for specific uses. The two primary types of AC motors are synchronous and asynchronous (or induction) motors. Synchronous motors operate at a constant speed, synchronized with the frequency of the power supply, making them suitable for applications requiring precise speed control. On the other hand, asynchronous motors are more commonly used due to their simplicity and robustness, making them ideal for industrial machinery, fans, and pumps.

The applications of AC electric motors are vast and varied. In the commercial sector, they are used in HVAC systems, conveyor belts, and washing machines, where energy efficiency and operational longevity are paramount. In manufacturing, AC motors drive equipment such as lathes and milling machines. The adaptability of AC motors allows them to excel in creating solutions for both minor residential projects and large industrial operations, underscoring their importance in modern technology and engineering. Understanding these distinctions and applications is crucial for engineers and technicians alike when designing and implementing effective systems.

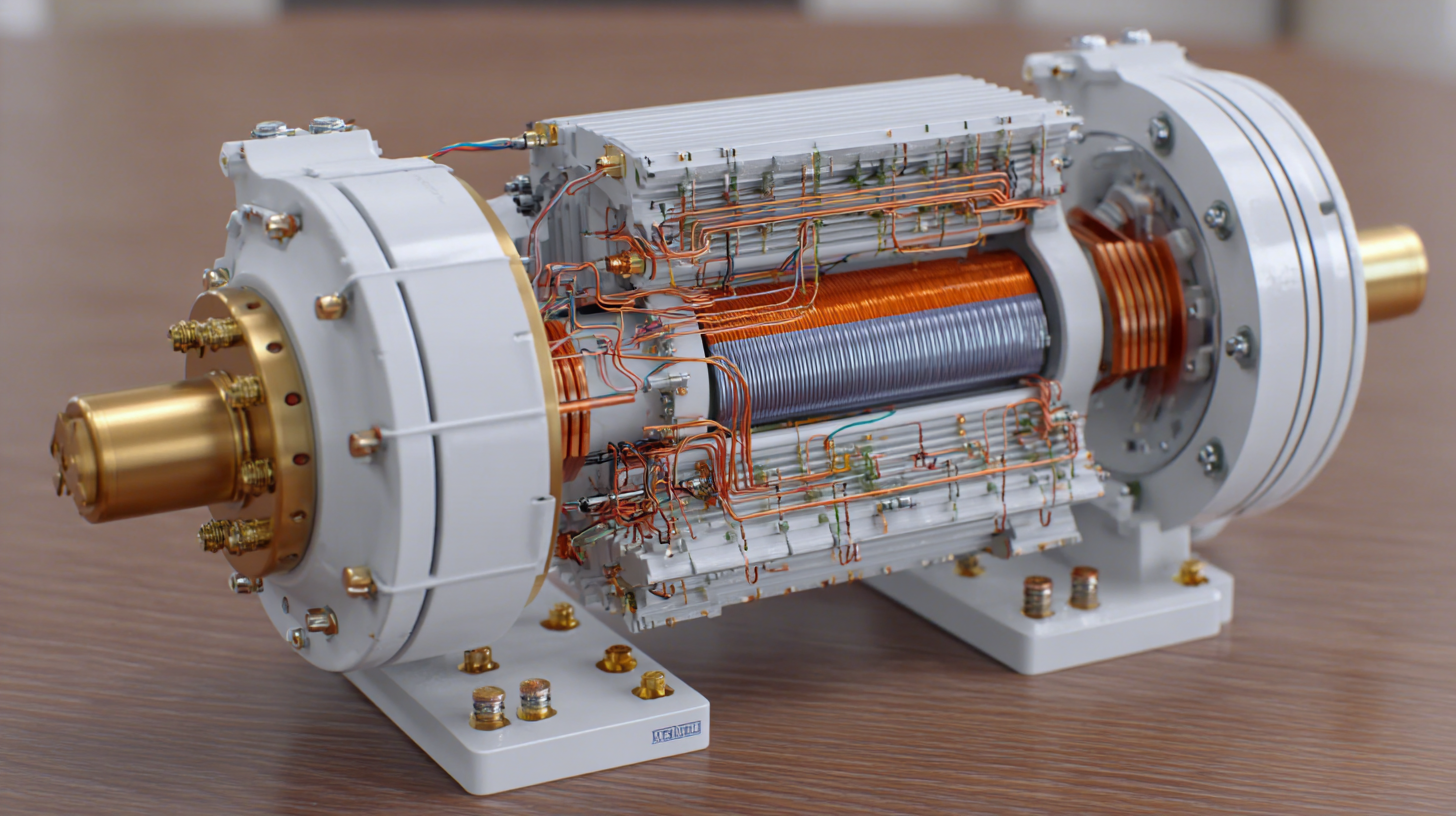

Key Specifications to Consider When Choosing AC Electric Motors

When selecting AC electric motors, understanding key specifications is crucial to making an informed choice. One primary factor is the motor's power rating, typically measured in horsepower or kilowatts. This rating determines how much load the motor can handle and is essential for aligning motor capabilities with application requirements. Additionally, the efficiency rating, often expressed as a percentage, indicates how effectively the motor converts electrical energy into mechanical energy, impacting operational costs over time.

Another vital specification is the speed rating, which refers to the motor's revolutions per minute (RPM). Depending on the application, you may require a motor that operates at a specific speed or one that offers variable speed capabilities. Furthermore, considering the motor's torque characteristics is important, particularly in applications requiring high starting torque. By examining these specifications—power, efficiency, speed, and torque—you can strategically assess which AC electric motor best suits your specific needs, ultimately leading to enhanced performance and energy savings.

Comparative Analysis of Single-Phase vs. Three-Phase Motors

When comparing single-phase and three-phase motors, it's essential to evaluate their performance, efficiency, and suitability for various applications. Three-phase induction motors (TIMs) are predominantly used in industrial settings due to their robust performance and higher efficiency. According to recent studies, TIMs can achieve efficiency levels up to 95%, significantly reducing operational costs over time. They also handle unbalanced supply conditions better, making them reliable for continuous duty applications.

On the other hand, single-phase induction motors, while having lower efficiency—typically around 70-85%—are more commonly used in residential settings and small appliances due to their lower installation costs and simpler design. Research indicates that advancements in technology, such as the introduction of cost-effective converters for single-phase machines, have improved their performance and energy efficiency, addressing previous limitations. For example, recent simulations have demonstrated that implementing fuzzy logic control can optimize single-phase motor performance, narrowing the efficiency gap compared to their three-phase counterparts. The continuous innovation in motor technology highlights an evolving landscape where both motor types can be tailored for specific use cases, influencing energy consumption and operational efficiency across various sectors.

Efficiency Ratings and Performance Metrics of AC Motors

When evaluating AC electric motors, efficiency ratings and performance metrics are crucial for ensuring optimal operation in various applications. According to the Electric Power Research Institute (EPRI), the efficiency of high-efficiency AC motors can exceed 95%, significantly reducing energy consumption and operational costs. This is especially important in industrial settings where motors are often run for long hours. Premium efficiency motors, often classified as NEMA Premium, not only meet stringent efficiency ratings but also contribute to lower lifetime costs through enhanced reliability and reduced heat generation.

Performance metrics, such as torque, speed regulation, and power factor, are fundamental to understanding an AC motor's capabilities. The Department of Energy (DOE) indicates that high-performance AC motors typically maintain a power factor of 0.9 or higher, promoting better energy usage and reduced electrical losses. Speed regulation, defined as the ability of a motor to maintain a steady speed under varying load conditions, is another critical performance attribute, with some advanced models achieving regulation levels of ±1% or better. These specifications not only enhance the functional characteristics of the motors but also support sustainability initiatives by minimizing wasteful energy practices in both commercial and residential applications.

Unveiling the Specifications of the Best AC Electric Motor: A Comprehensive Technical Review

| Model | Power Rating (kW) | Efficiency (%) | Torque (Nm) | Speed (RPM) | Cooling Type |

|---|---|---|---|---|---|

| Model A | 15 | 95 | 30 | 1500 | Air-Cooled |

| Model B | 22 | 92 | 45 | 3000 | Water-Cooled |

| Model C | 5 | 90 | 10 | 1000 | Air-Cooled |

| Model D | 18.5 | 93 | 35 | 1800 | Air-Cooled |

| Model E | 30 | 96 | 60 | 1500 | Water-Cooled |

Future Trends in AC Electric Motor Technology and Innovation

The future of AC electric motor technology is poised for transformative innovations, driven by advancements in material science and the increasing demand for energy efficiency. According to a report by MarketsandMarkets, the AC motor market is expected to reach $30 billion by 2025, growing at a CAGR of 6.6% from 2020 to 2025. This growth is largely influenced by the industry’s shift toward sustainable solutions, with manufacturers emphasizing on reducing energy consumption while maximizing performance.

Emerging technologies such as artificial intelligence and IoT are set to reshape the design and functionality of AC electric motors. The integration of smart sensors and predictive maintenance technologies is expected to enhance operational efficiency, enabling motors to adapt in real-time to changes in load and environment. For instance, a study by Grand View Research highlights that the introduction of smart motor control systems could lead to energy savings of up to 30% in industrial applications. As industries continue to embrace electrification and automation, the push towards advanced AC motor technologies will pave the way for not only improved performance but also significant cost savings for end-users, heralding a new era in electric motor innovation.

-

Phone

Phone

0086-13586199782

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top