Top Aluminum Motor Types for Efficient Performance and Durability?

The demand for efficient and durable solutions is ever-growing in various industries. Aluminum motors stand out due to their lightweight construction and high efficiency. Experts have noted their advantages over traditional materials. John Smith, a leading expert in the aluminum motor industry, once stated, "Aluminum motors are not just about weight; they redefine performance."

These motors significantly enhance energy efficiency. Their design allows for optimal heat dissipation. However, challenges remain, such as potential corrosion and material fatigue. Understanding these factors is vital for maximizing longevity. Companies must focus on innovative designs and robust testing procedures.

In a competitive landscape, durability is key. Ensuring that aluminum motors can withstand rigorous conditions is essential. As the industry evolves, continuous improvement is necessary. Striking a balance between performance and reliability presents a challenge. Yet, the potential of aluminum motors is undeniable in driving future advancements.

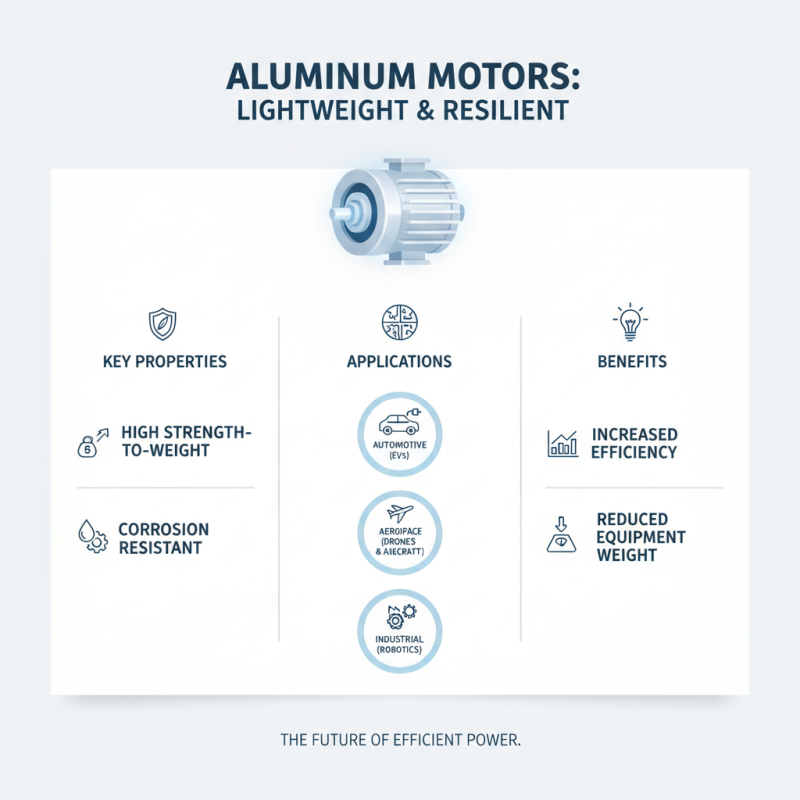

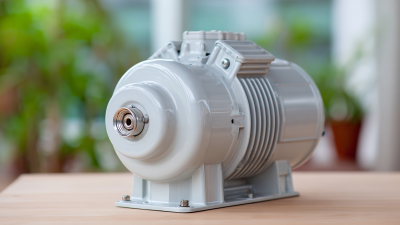

Overview of Aluminum Motors in Modern Applications

Aluminum motors have become essential in various modern applications due to their lightweight and resilient properties. These motors provide efficient performance in diverse fields like automotive, aerospace, and industrial machinery. Their high strength-to-weight ratio makes them ideal for reducing overall equipment weight while maintaining durability. This is crucial in environments where every gram counts, such as in aircraft and electric vehicles.

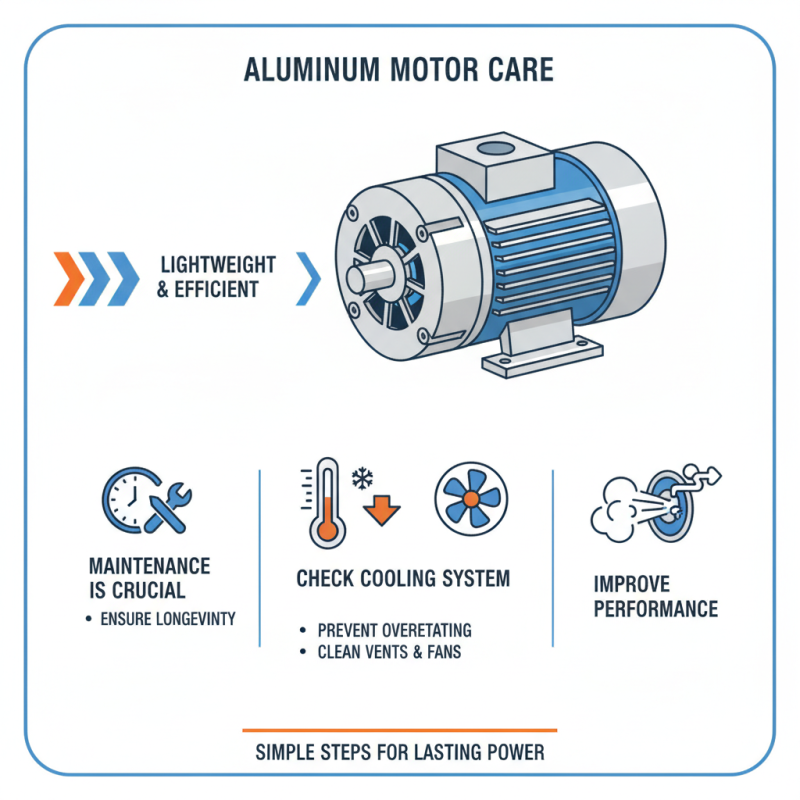

In addition to their physical advantages, aluminum motors also exhibit thermal conductivity. This characteristic ensures efficient heat dissipation, which extends the motor's lifespan. However, it's worth noting that improper cooling can lead to performance issues. Maintenance often requires checking for overheating, which some users might overlook. Furthermore, as technology evolves, the demand for aluminum motors in renewable energy applications rises. That shift highlights the need for continuous adaptation and innovation in motor design.

Key Benefits of Using Aluminum in Motor Construction

Aluminum has become a popular choice for motor construction due to its remarkable benefits. One of the primary advantages is its lightweight nature. This can lead to better efficiency in performance, as lighter motors require less energy to operate. A lighter motor can also enhance overall system agility, with quicker response times.

Durability is another crucial factor. Aluminum is resistant to corrosion, which is vital for motors used in various environments. This resistance can prolong the lifespan of the motor and reduce maintenance costs. While aluminum is strong, it can be prone to deformation under extreme stress. Engineers must consider this when designing aluminum motors.

Heat dissipation is an essential feature, too. Aluminum's conductive properties help in managing heat more effectively. Efficient cooling prevents overheating and ensures consistent performance. However, the use of aluminum does pose some challenges. It may require careful engineering to balance its strengths and weaknesses. Each design must be approached thoughtfully to ensure the motor performs efficiently and lasts as long as intended.

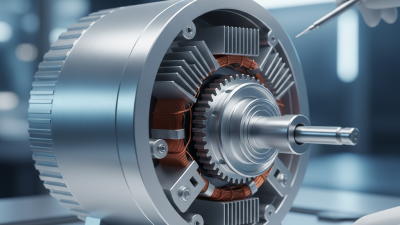

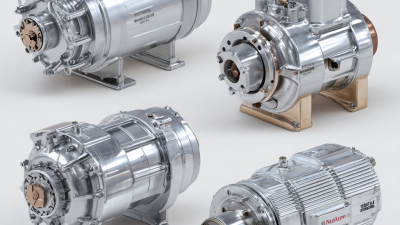

Types of Aluminum Motors: A Comparative Analysis

When discussing aluminum motors, various types come to mind. Each has unique features, suitable for different applications. The key is to select a motor that aligns with specific needs. High-efficiency models are often prioritized for their performance. Their lightweight design aids in better energy management. Moreover, they show resilience under high temperatures.

Comparing motors requires attention to several factors. For instance, torque output is vital for heavy-duty tasks. Some motors excel in quiet operation, reducing noise pollution. Others are designed for durability in challenging environments. Performance, however, can sometimes have trade-offs. An efficient motor may lack raw power, affecting certain uses.

Understanding these nuances is essential. Each motor's strengths and drawbacks should inform decisions. Testing performance in real-world scenarios can uncover potential issues. This step is often overlooked, yet it greatly impacts outcomes. Selecting the right aluminum motor demands careful consideration of both capabilities and limitations.

Factors Influencing Performance and Durability of Aluminum Motors

When discussing aluminum motors, several factors influence their performance and durability. One crucial aspect is the quality of aluminum used in manufacturing. High-grade aluminum can withstand corrosion and heat better than lower grades. Reports indicate that motors made with premium aluminum have a lifespan that is 30% longer than those using standard materials. However, not all manufacturers prioritize material quality, leading to inconsistent performance among different products.

Another significant factor is the design of the motor itself. A well-engineered motor can enhance efficiency by 15% or more. Features such as improved cooling systems and optimized rotor designs contribute to lower energy losses. Yet, many motor designs still suffer from inefficiencies. This gap suggests a need for ongoing innovation and refinement in the industry. The choice of insulation materials and winding techniques also plays a role in enhancing durability, with some options reducing wear under high-stress situations.

In addition, environmental conditions cannot be overlooked. Motors exposed to extreme temperatures or humidity may suffer quicker degradation. Reports reveal that motors operating in harsh environments face a double risk of failure compared to those in controlled settings. This highlights the importance of selecting the right aluminum motor for specific applications and conditions. Each factor culminates in a complex web of performance and longevity issues that require careful consideration.